Top 10 CFD Applications Fueling Innovation in 2025

Ever wondered how a Formula 1 car can stick to the road at incredible speeds, or how a data center housing thousands of servers keeps from melting? The answer often involves a powerful engineering tool called Computational Fluid Dynamics (CFD). In simple terms, CFD uses complex physics and powerful computers to simulate the movement of fluids (like air and water) and heat. It's like having a virtual wind tunnel or a digital laboratory right on your computer, allowing engineers to test, predict, and optimize designs before ever building a physical prototype.

As technology becomes more complex and the pressures to innovate quickly and efficiently increase, the role of CFD is becoming nonnegotiable. Companies across most major industries with variety of CFD applications are leveraging computational fluid dynamics simulations to solve their toughest challenges, from reducing emissions to designing life-saving medical devices. While not all-inclusive, this list explores the ten most requested and impactful applications for CFD services that we have seen as CFD Consultants in 2025, showcasing how digital simulation is turning today's engineering challenges into tomorrow's breakthroughs.

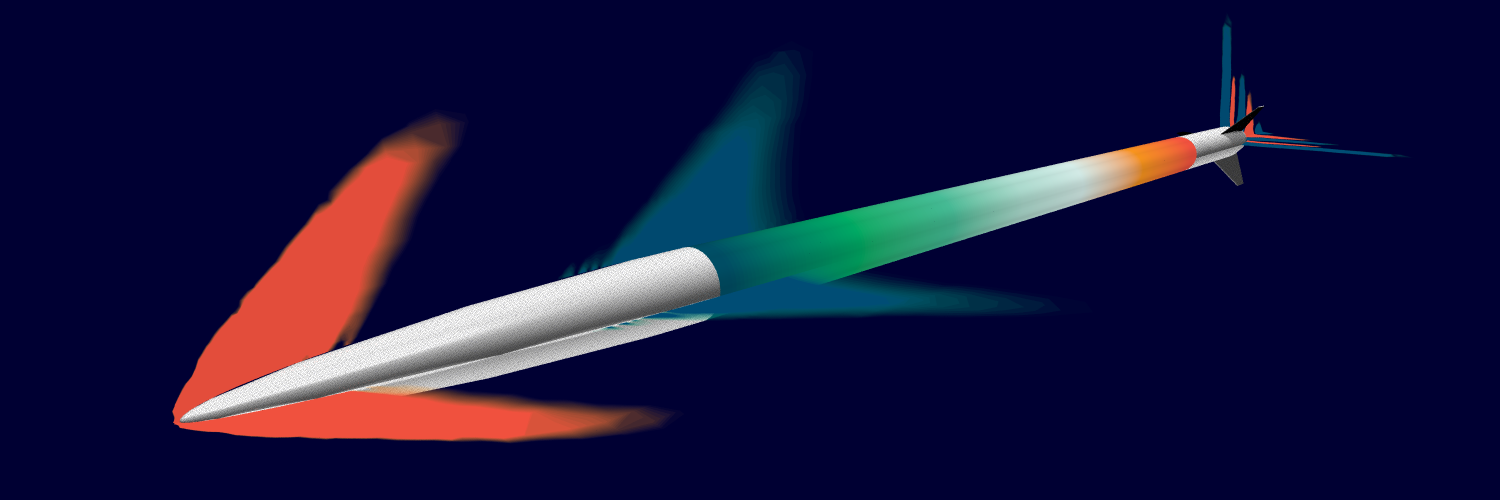

External Aerodynamics in Aerospace Engineering is one of the most well-known and historically significant uses for Computational Fluid Dynamics.

Aerospace Engineering

CFD is quickly becoming an industry standard for designing and analyzing everything from aircraft to spacecraft. It is heavily used to model external aerodynamics, predict lift and drag, and optimize fuel efficiency. Furthermore, it plays a critical role in simulating combustion in jet engines and analyzing the thermal management of aircraft systems. NASA continues to work toward their CFD Vision 2030, and all commercial CFD software packages release CFD software updates for aerospace applications every year, improving CFD modeling complexity and capabilities.

Pushing the Boundaries of Flight

In aerospace, performance and safety are paramount. Engineers use advanced CFD software to simulate the extreme conditions aircraft face, from the intense heat of engine combustion to the complex airflow over a wing during takeoff. This virtual testing allows for the rapid exploration of new designs. For example, by simulating airflow and heat transfer simultaneously, engineers can optimize the placement of electronic components and design more effective cooling systems, preventing overheating at 30,000 feet. This multi-physics approach is crucial for developing the next generation of more efficient and reliable aircraft, significantly reducing the time and cost associated with traditional physical prototyping. CFD Simulation and Wind Tunnel Testing are used in combination. While CFD can reduce the scope of expensive wind tunnel testing, aerospace engineers rely on wind tunnel testing for predicting turbulent flows.

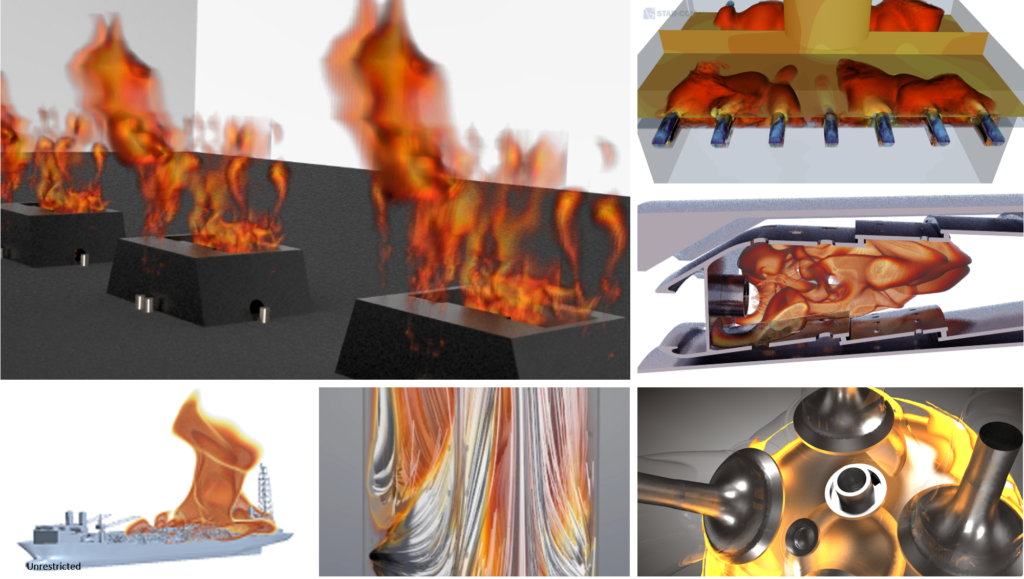

Ammonia and Diesel jets at various injection timings and angles are studied in Simcenter STAR-CCM+

Automotive Industry

In the automotive sector, CFD is crucial for vehicle aerodynamics to reduce drag and improve fuel economy. It's also essential for optimizing engine performance by simulating in-cylinder combustion, cooling systems, and exhaust after-treatment. Additionally, automotive CFD is used to enhance passenger comfort through climate control simulations.

Modern ENGINE-ering

While aerodynamics get a lot of attention, some of the most complex fluid dynamics in a vehicle happen inside the engine. While simulating the combustion process within a cylinder is challenging, it's one that CFD is equipped to handle. Engineers can model the injection of fuel, the mixing with air, the ignition, and the resulting combustion and emissions with incredible detail. This allows them to design pistons, valves, and fuel injectors that maximize power and efficiency while minimizing harmful pollutants like NOx and soot. This level of insight accelerates the engine design process from months to weeks, giving manufacturers a critical edge in a competitive market.

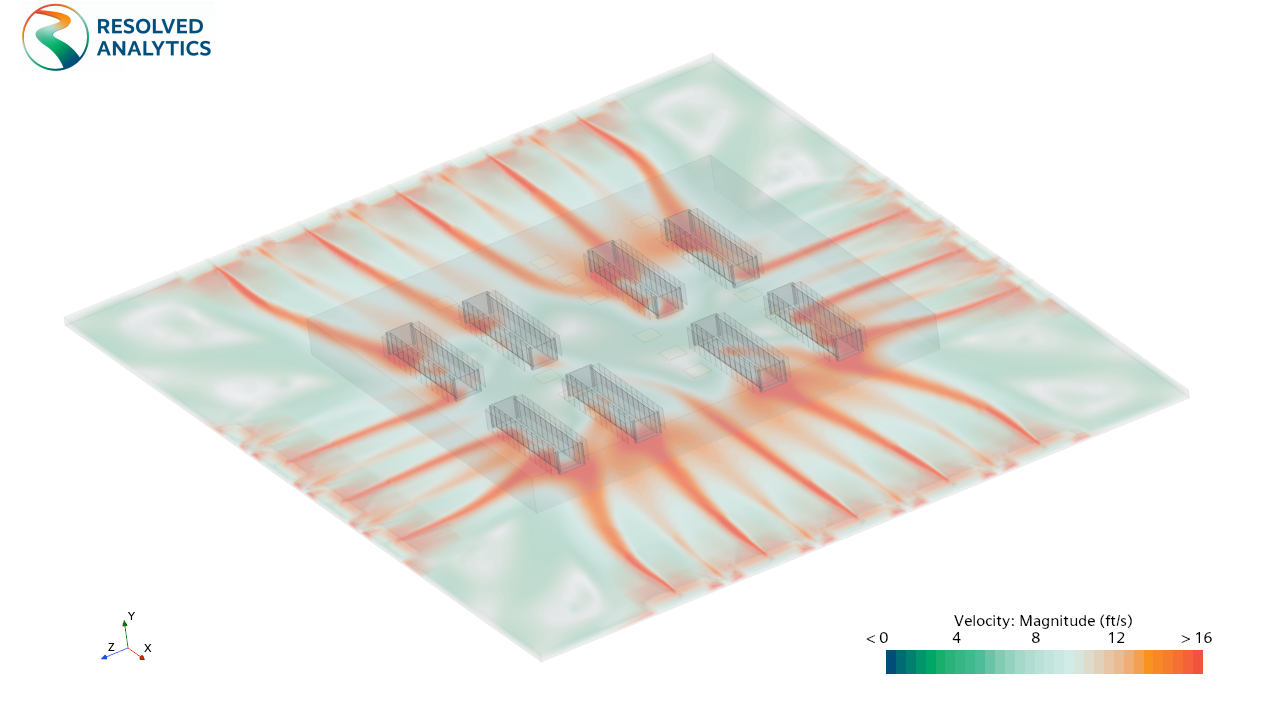

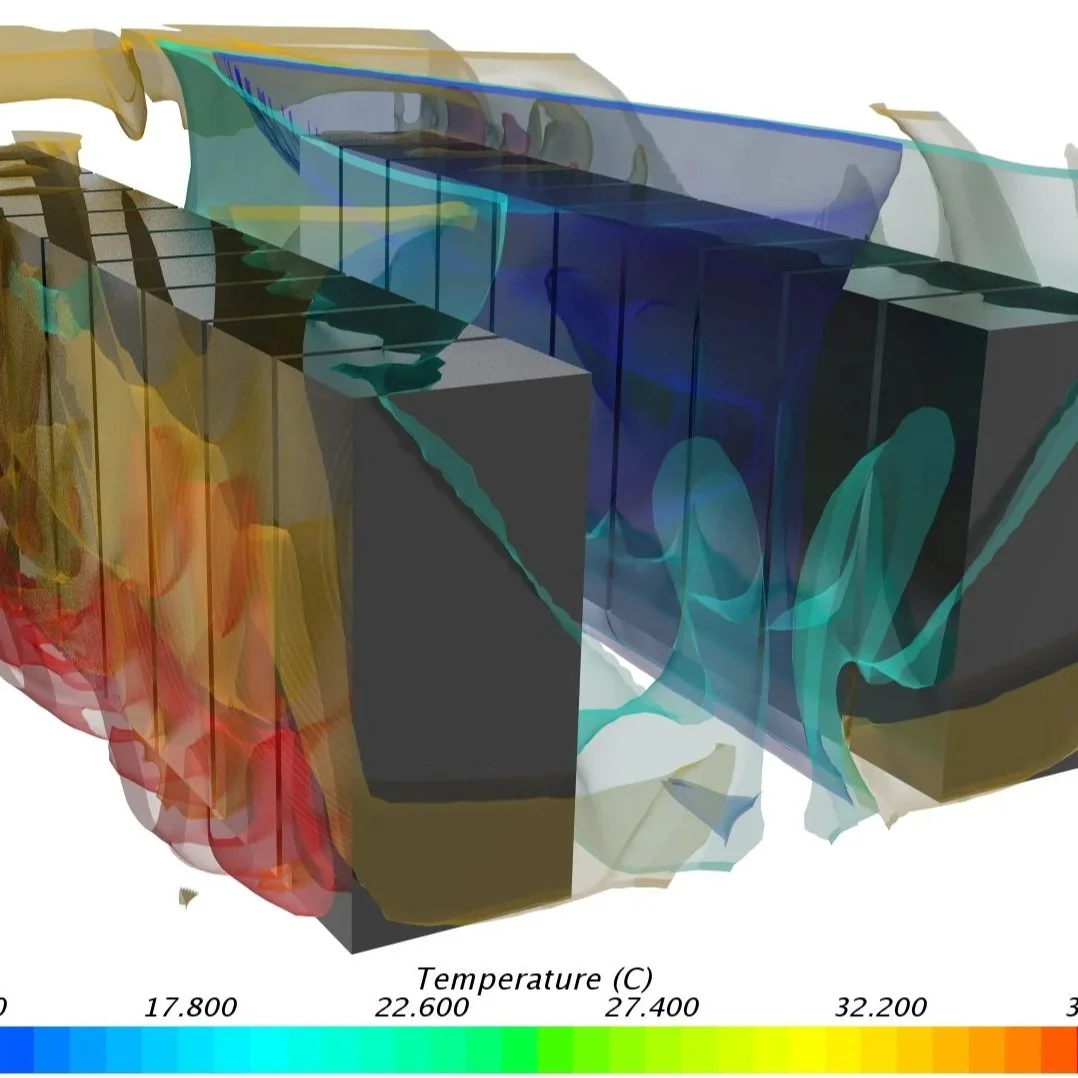

CFD Simulation of Underfloor Cooling in a Data Center

Data Centers

While related to electronics cooling, data center CFD is a specialized field focused on the massive scale of ensuring thermal stability for entire buildings packed with servers. Optimizing airflow and cooling is crucial for reliability (preventing outages) and managing the enormous energy costs associated with data centers.

Cooling The Cloud

A modern data center can consume as much energy as a small city, with a huge portion of that going towards cooling. CFD is the go-to tool for designing and optimizing data center cooling strategies. Engineers can model an entire server hall, simulating how cool air from the floor grilles flows through server racks and how hot exhaust air is captured and removed. This allows them to perfect hot-aisle/cold-aisle containment, test the effectiveness of liquid cooling solutions for high-density racks, and ensure there are no hot spots that could cause a server to fail. By optimizing airflow, data centers can dramatically improve their Power Usage Effectiveness (PUE), leading to millions of dollars in energy savings.

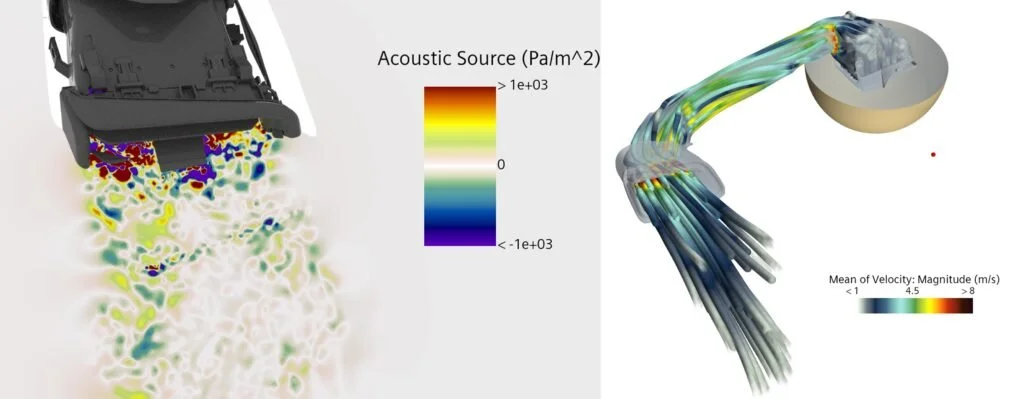

Hybrid acoustic models in Simcenter STAR-CCM+ identify key noise sources in HVAC ducts.

Heating, Ventilation, and Air Conditioning (HVAC)

For the HVAC industry, CFD is a key tool for designing and optimizing systems in buildings of all sizes. It helps in analyzing airflow, temperature distribution, and contaminant dispersal to ensure thermal comfort and high indoor air quality while minimizing energy consumption. HVAC CFD is no longer a luxury but a necessity for innovation.

Meeting Modern HVAC Challenges

The HVAC industry is facing immense pressure from multiple directions: increasingly strict energy efficiency standards, the mandatory phase-out of high-warming-potential refrigerants, and consumer demand for smart, connected systems. A traditional build-and-test approach is too slow and costly to keep up.

This is where digital engineering and CFD come in. Companies are using simulation to tackle these challenges head-on. For instance, when developing systems for new, mildly flammable refrigerants like R32, CFD is used to model potential leakage scenarios within a unit. This ensures the design is safe and compliant without the risk and expense of repeated physical tests. Similarly, leading companies like Daikin use CFD to optimize the fan blade designs on their outdoor units, successfully reducing noise levels by several decibels while maintaining cooling performance—achieving this in half the time it would have taken with physical prototyping alone. From the component level to full system-level performance, CFD software is helping HVAC engineers innovate faster and smarter.

As decarbonization and environmental impact become central to global industry, Selective Catalytic Reduction (SCR) continues to be a primary solution for achieving stringent emission reduction targets, and CFD is an essential tool for optimizing these systems.

Energy Sector

CFD is widely used in both renewable and traditional energy sectors. In renewable energy, it's instrumental in designing and placing wind turbines for optimal performance. For conventional CFD for power generation equipment, it is used to model combustion in boilers, optimize the performance of turbines, and design cooling systems.

Optimizing Power Generation

In large industrial power plants, even small improvements in efficiency can lead to massive fuel savings and reduced emissions. Take, for example, a stoker boiler used in a pulp mill. These complex systems can suffer from issues like incomplete combustion, leading to high carbon monoxide (CO) levels and wasted energy. Using CFD, engineers can build a detailed 3D model of the boiler and simulate the entire combustion process. This allows them to pinpoint problem areas, such as poor air distribution, and test potential solutions virtually. By adjusting airflow rates and injection locations in the model, they can find the optimal setup to improve combustion, lower CO, and ensure the boiler runs as efficiently as possible.

Beyond the boiler, CFD is essential for environmental compliance. We use it to optimize Selective Catalytic Reduction (SCR) systems, where the goal is to mix ammonia into exhaust gases with extreme precision. By simulating the flow through these massive ducts, we can ensure maximum NOx removal with minimum pressure drop, helping plants meet 2025 emissions standards without sacrificing performance.

The FDA now recognizes simulation-based development and virtual prototyping as powerful allies to traditional clinical trials. By leveraging these digital tools to supplement experimental testing, manufacturers can navigate regulatory pathways more efficiently and bring life-saving treatments to patients faster.

Biomedical and Healthcare

The biomedical field utilizes CFD for a variety of applications, from simulating blood flow through arteries to analyzing airflow in the respiratory system. A particularly critical use is in the pharmaceutical industry, ensuring that temperature-sensitive medicines are stored safely and effectively.

Ensuring Pharmaceutical Safety

For many modern medicines, maintaining a precise temperature range during storage is not just a recommendation—it's a regulatory requirement. A deviation of just a few degrees can render a multi-million dollar batch of product useless. CFD for pharma storage provides a way to digitally validate the performance of storage facilities like freezers and cold rooms. Engineers can simulate the airflow and heat distribution inside the facility to identify potential hot or cold spots, predict how a door opening will affect the internal temperature, and ensure that every pallet of product remains within its safe limits. This proactive approach helps mitigate risk, ensure product quality, and meet stringent regulatory standards.

An animation from a Computational Fluid Dynamics (CFD) simulation of the open computer server architecture known as Barreleye. Streamline colors represent the temperature of fluid parcels as they pass through the server and absorb heat from the various electronic components.

Electronics Cooling

With the increasing power density of electronic components, thermal management is a major concern. CFD for electronics cooling is essential for simulating airflow and heat transfer within electronic devices, from smartphones to the complex electric motors in vehicles, ensuring optimal performance and preventing overheating.

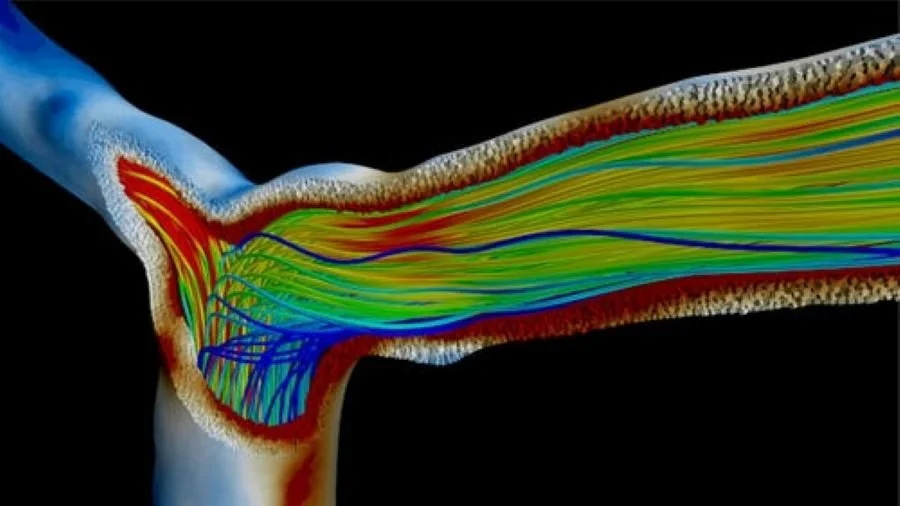

Keeping Critical Components Cool

As electronics become more powerful and compact, dissipating the heat they generate becomes a primary design challenge. In applications like electric vehicles, components such as the motor and inverter generate significant heat. Overheating can reduce efficiency and lead to premature failure. CFD allows engineers to design and test sophisticated cooling systems, such as liquid cooling jackets that wrap around a motor. By simulating the flow of coolant through intricate channels, they can optimize the design to ensure uniform and effective heat removal, maximizing the performance and reliability of the entire system. These fluid simulations are crucial for the advancement of electrification.

Whether you are simulating gas turbines, internal combustion engines, or industrial furnaces, capturing accurate flame physics is critical. Simcenter STAR-CCM+ provides a scalable range of combustion models tailored to your specific requirements for accuracy and project deadlines.

Manufacturing and Chemical Processing

In the manufacturing and chemical processing industries, CFD is used to design and analyze a wide range of equipment, including reactors, mixers, and separation columns. It helps in optimizing process efficiency, improving product quality, and ensuring operational safety.

Enhancing Process Efficiency

Effective mixing is fundamental to many chemical processes. Whether combining reactants or ensuring a uniform temperature in a large vessel, improper mixing can lead to low product yield and quality issues. CFD for chemical processing allows engineers to visualize the flow patterns inside a reactor or mixing tank. They can test different impeller designs, speeds, and baffle configurations to eliminate dead zones and achieve the perfect mix. This virtual optimization saves enormous amounts of time and resources compared to building and testing physical pilot-scale mixers, leading to more efficient and reliable production processes.

Beyond simple mixing, modern CFD allows us to model the chemistry itself. By using complex reacting flow models, we can predict not just how the fluid moves, but the actual chemical yield and selectivity—allowing engineers to optimize the reactor's output before the first batch is ever run.

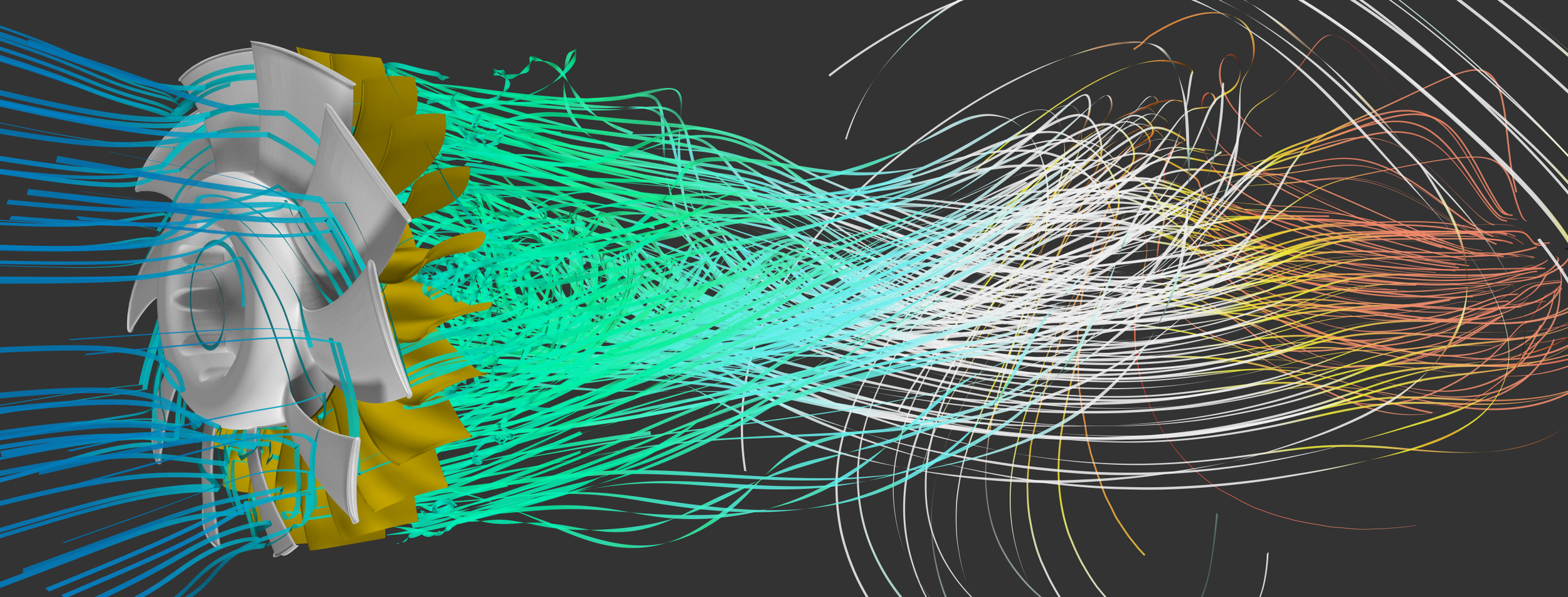

Advances in CFD software allow engineers to push the limits of fan design, delivering higher efficiency, better performance, and extended service life. By simulating the complex airflow through the blades, CFD pinpoints specific design flaws that traditional testing might miss.

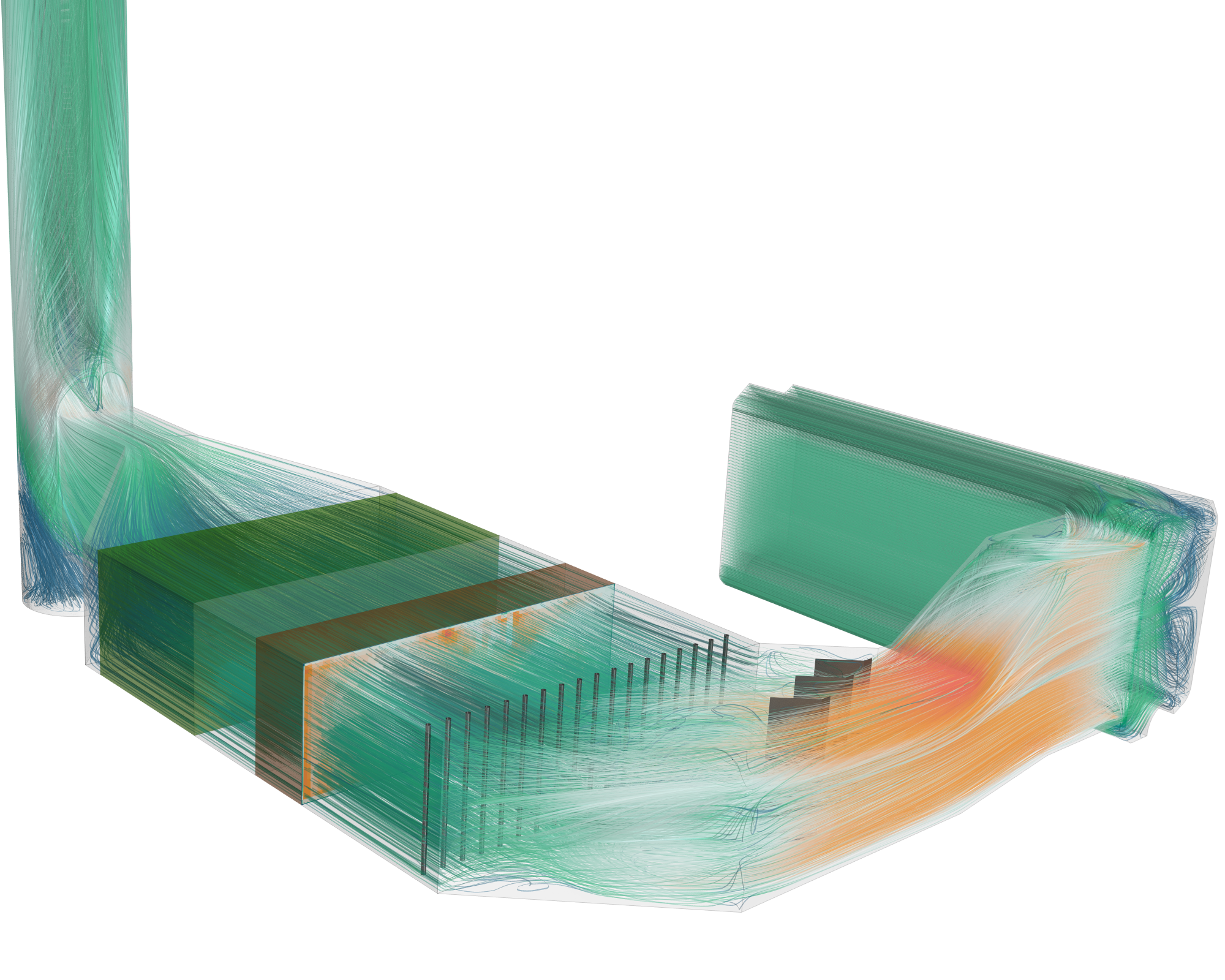

Turbomachinery

The design of turbomachinery—such as pumps, compressors, and turbines—heavily relies on CFD. It is used to analyze the complex, high-speed, and often turbulent flow patterns within these devices to improve their efficiency, performance, and reliability.

Powering The World More Efficiently

Turbomachinery is the heart of everything from jet engines to power plants. The performance of these devices is dictated by the incredibly complex interaction of spinning blades with fluids. CFD for turbomachinery gives designers the ability to peer inside a virtual machine and see exactly how the air, gas, or liquid is behaving. This insight allows them to sculpt blade shapes that minimize energy losses, reduce damaging vibrations, and maximize efficiency. The continued advancements in CFD software enable the simulation of these complex systems with higher fidelity than ever, driving the incremental gains in efficiency that power our world.

Simcenter STAR-CCM+ provides a robust framework for battery safety analysis through the ability to model detailed cell-level thermal runaway using the Homogeneous Multiphase Complex Chemistry (HMMC) model.

Battery Technology

A rapidly growing application for CFD is in the design and analysis of batteries, particularly for electric vehicles. CFD for battery storage is used to simulate the thermal behavior of battery packs, ensuring they operate within a safe temperature range and optimizing their cooling systems for better performance and longevity.

Driving The Future Of Battery Safety

The performance, lifespan, and safety of a lithium-ion battery are all critically dependent on its temperature. Overheating can lead to accelerated degradation and, in the worst case, a dangerous event called thermal runaway. To prevent this, companies like Forsee Power use CFD to design and validate the thermal management systems for their battery packs. By creating a detailed "digital twin" of a battery module, they can simulate how heat is generated during rapid charging or discharging and test various cooling strategies—whether with air, cooling plates, or liquid coolants. This simulation-driven approach allows them to develop safer, longer-lasting batteries and bring them to market faster.

The diverse and powerful CFD applications highlighted here are just the beginning. As computational power grows and CFD software becomes even more sophisticated, its role in solving the world's most complex engineering problems will only expand.

Ready to see how simulation can transform your product development cycle? Learn more about Computational Fluid Dynamics consulting and discover how our expertise can help you innovate.