The Ultimate Guide to Computational Fluid Dynamics (CFD) for Data Center Optimization

Table of Contents

What are the Compounding Pressures on Modern Data Centers?

What is Data Center CFD? A Virtual Look Inside

Core CFD Applications: Ensuring Reliability & Optimizing Data Center Design

What is a Data Center Digital Twin?

Frequently Asked Questions (FAQ) about Data Center CFD

The Resolved Analytics Advantage: A Modern Engineering Approach

Computational Fluid Dynamics (CFD) empowers you to create environments that are not just cool, but optimized for efficiency, reliability, and growth.

In the high-density, high-stakes world of data centers, where each kW of IT load demands precise thermal management, CFD is more than useful—it's essential.

The Challenge of Data Center Energy Consumption

Data centers are the unseen engines of our connected world, but they come at a significant energy cost. These facilities are responsible for up to 3% of global electricity consumption today and are projected to touch 4% by 2030. An average hyperscale facility consumes 20-50MW annually, enough electricity to power up to 37,000 homes. By the end of 2024, the computing capacity of data centers under construction in North America reached a record-high 6,350 MW—more than double the previous year. [1]

Cooling and HVAC systems are responsible for up to 40% of this energy consumption. This guide explains how Computational Fluid Dynamics (CFD), a critical simulation technology, is used to optimize thermal management and dramatically improve data center energy efficiency. [2]

What are the Compounding Pressures on Modern Data Centers?

Data center operators face several overlapping challenges that make efficiency and reliability more critical than ever:

Energy Costs & Stalled PUE:

PUE is the ratio of the total amount of power used by a computer data center facility to the power delivered to computing equipment. The drive to lower Power Usage Effectiveness (PUE) is constant. While early gains were significant, the industry average has stalled for the fifth consecutive year, with the 2024 average PUE holding steady at 1.56, indicating a need for more advanced methods to achieve further improvements. [3] According to NREL, the U.S. Department of Energy's primary national laboratory for energy systems, Data centers focusing on efficiency typically achieve PUE values of 1.2 or less. [2]

Increasing Power Density:

Increasing Power Density & AI Workloads: As server technology advances, power densities per rack are rising. The rise of AI is the primary driver, with some estimates suggesting that training a single large AI model could require a power draw of 25.3 MW and consume as much energy as powering San Francisco for three days. This makes traditional air cooling insufficient and pushes the need for advanced solutions like liquid cooling. [4]

Regulatory Compliance & Sustainability Metrics:

While there are currently no legally binding federal energy standards for private-sector data centers in the U.S., increased government scrutiny is coming. Regulations requiring operators to report on sustainability metrics are now passed or pending in regions including the EU and UK. However, the 2024 Global Data Center Survey found that fewer than half of operators are tracking key metrics like water usage (43%) and carbon emissions.

Uptime and Resiliency:

“Uptime Institute is an unbiased advisory organization focused on improving the performance, efficiency, and reliability of business critical infrastructure through innovation, collaboration, and independent performance certifications.” Data center uptime is the measure of a facility's reliability, representing the percentage of time it is operational and available to its users, often defined by the Uptime Institute Tier classifications (I-IV). As mission-critical facilities, data centers must meet strict uptime guarantees, where any interruption can lead to critical data and financial loss.

What is Data Center CFD? A Virtual Look Inside

Computational Fluid Dynamics (CFD) for data centers is a type of engineering simulation that uses numerical analysis to solve and analyze problems involving fluid flow and heat transfer. It allows designers and operators to build a virtual model of a data center to predict airflow and thermal performance before construction or to troubleshoot issues in an existing facility.

Computational Fluid Dynamics (CFD) visualization of wind velocity around a data center. This analysis helps optimize the placement of external cooling equipment and assess structural wind loads.

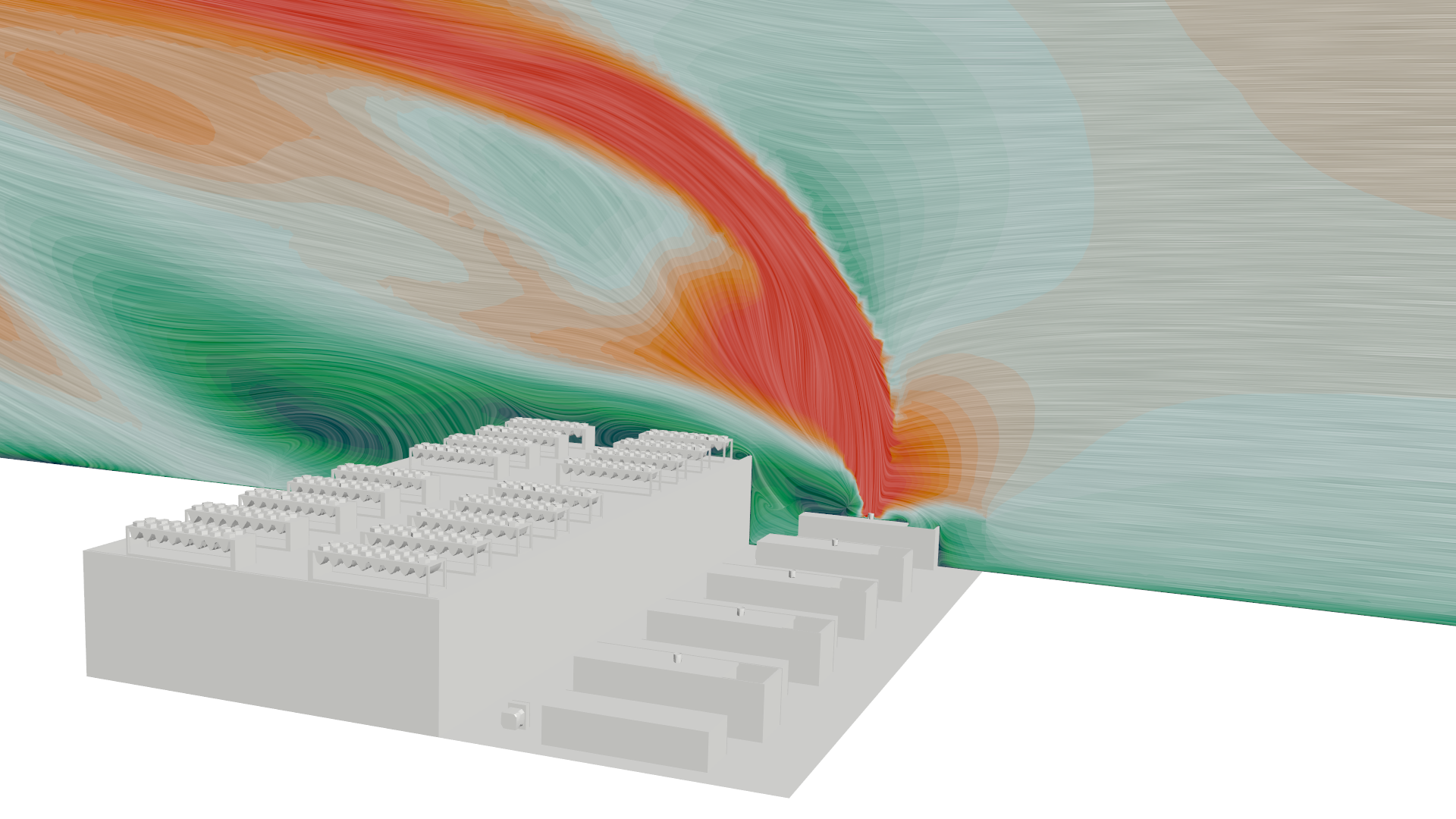

CFD simulation results showing the impact of wind on thermal exhaust plumes from data center cooling units. Understanding these patterns is key to optimizing equipment placement.

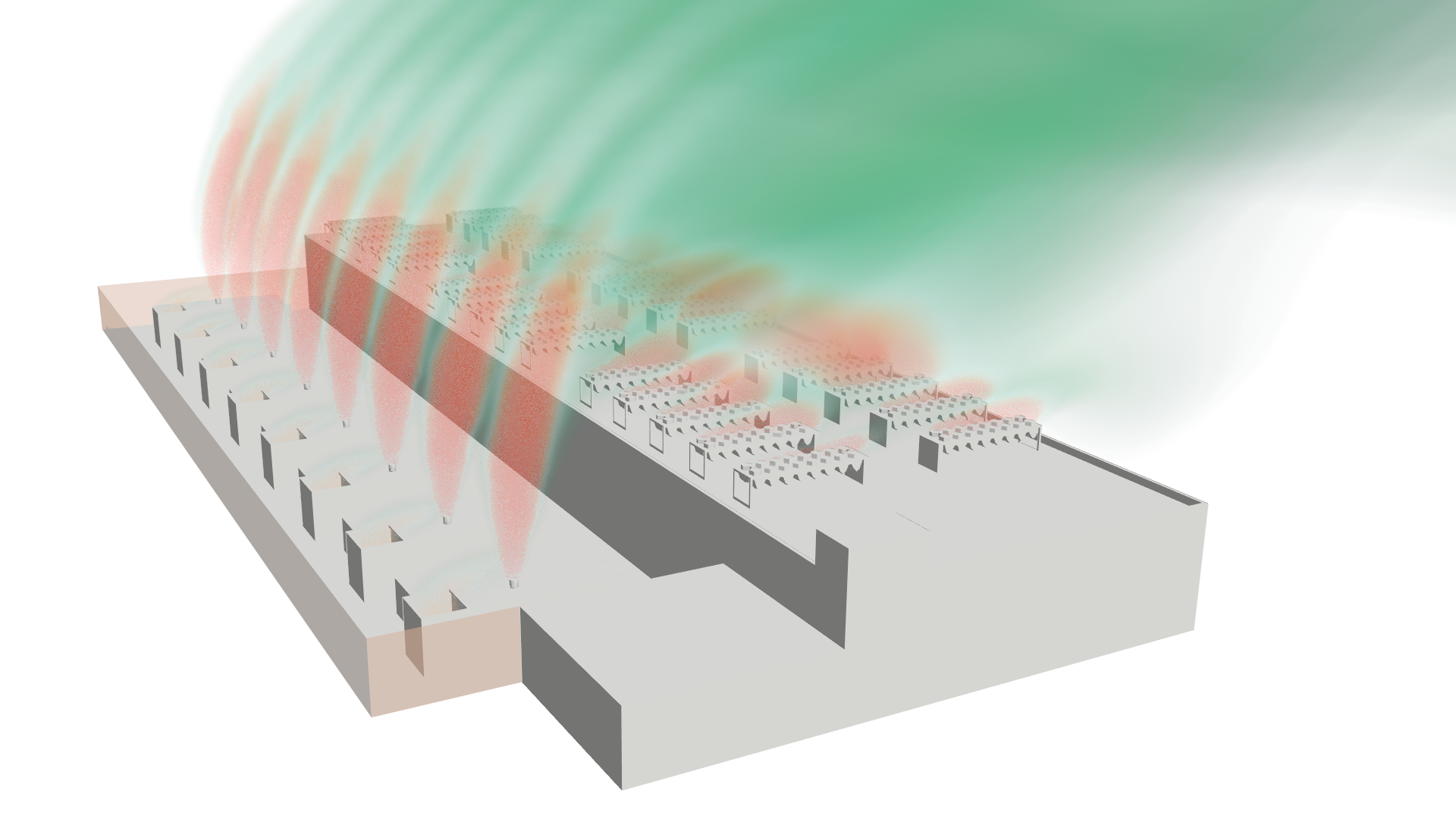

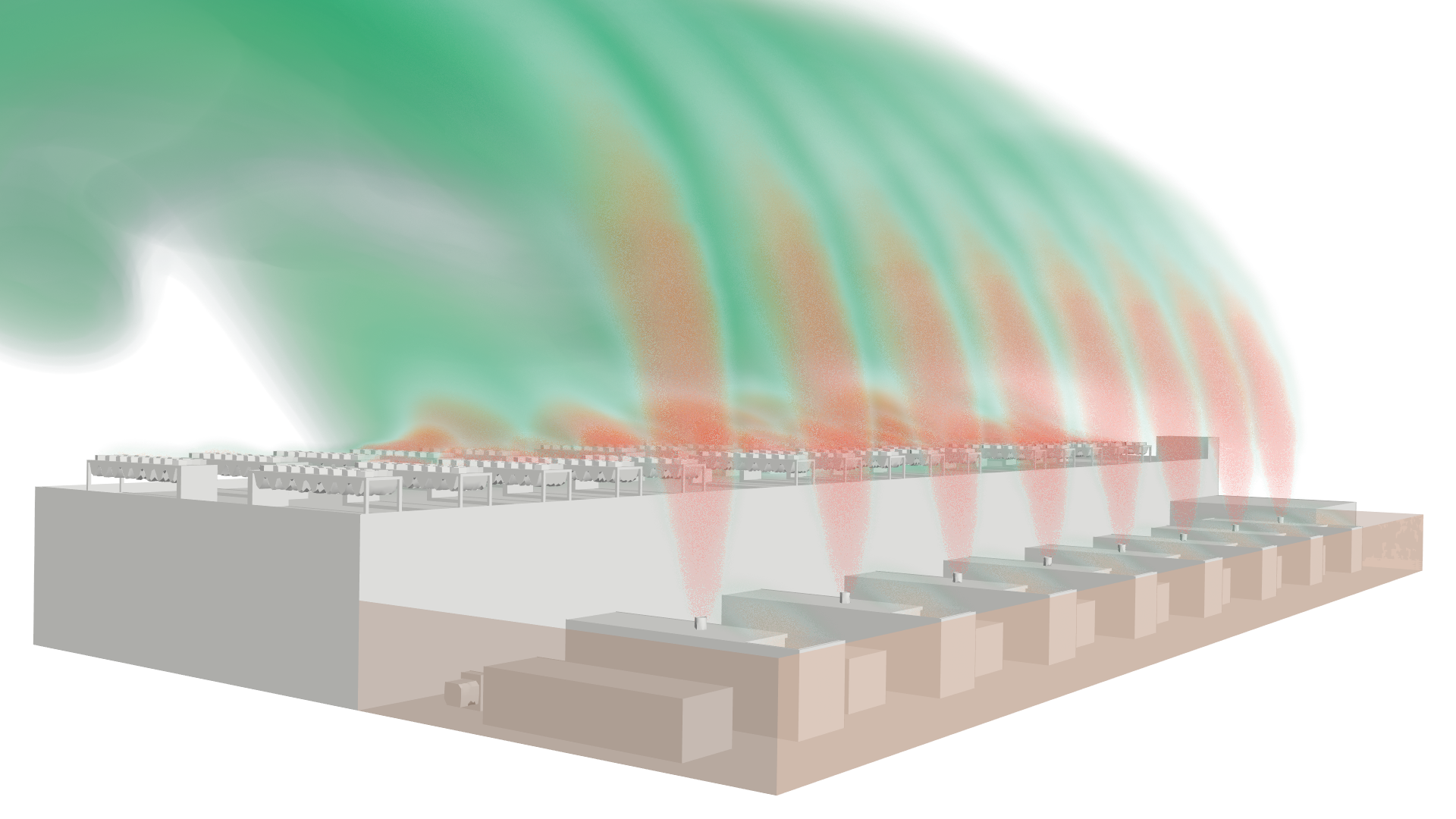

Visualization of Computational Fluid Dynamics (CFD) results showing thermal plumes from data center cooling exhaust. This analysis helps prevent hot air re-ingestion by intake vents.

Internal CFD:

This analysis focuses inside the data hall. It is used to visualize airflow from cooling units, identify hot spots on servers, optimize rack layouts, and validate hot/cold aisle containment strategies to prevent hot air recirculation.

External CFD:

This analysis focuses on the building's exterior. It helps determine the optimal placement of cooling towers and chillers by simulating how wind and weather could impact their performance, such as preventing hot exhaust from being re-ingested by cooling intakes .

Transient CFD:

This analysis simulates performance over time. It is crucial for assessing "thermal ride-through"—a data center's ability to keep equipment cool and operational during a brief power outage before backup generators kick in.

Core CFD Applications: Ensuring Reliability & Optimizing Data Center Design

CFD simulation helps architects and engineers improve building performance in several key areas (Resolved Analytics: CFD for Data Centers):

Optimizing Interior Airflow Management:

In data centers, a few degrees can mean the difference between uptime and costly downtime. CFD allows you to:

Model airflow at the rack level, identifying potential hot spots where server inlet temperatures exceed ASHRAE TC 9.9 guidelines.

Simulate the impact of different cooling strategies (raised floor, in-row, rear-door heat exchangers) on each server's thermal profile.

Optimize Computer Room Air Conditioning (CRAC) unit placement and airflow rates to target cooling precisely where it's needed, preventing over-provisioning.

Model hot aisle/cold aisle configurations to assess the extent of air mixing and recirculation.

Simulate how different containment systems (curtains, hard partitions, chimneys) affect airflow patterns and temperature gradients.

Analyze the impact of rack placement, blanking panels, and perforated tile locations on maintaining pressure differentials in contained zones.

The "Divide & Conquer" study showed that optimizing airflow with partitions could reduce server fan power by 32.6% and CRAH blower load by 13.8%.

Validating Advanced Cooling Systems:

As power density increases, CFD becomes essential for designing and de-risking next-generation cooling technologies like:

Direct Liquid Cooling (DLC): Designing cold plates and flow paths for direct-to-chip cooling.

Immersion Cooling: Simulating two-phase flow in open bath immersion systems to manage intense heat from high-density servers.

Ensuring Reliability and Compliance:

Compliance: The private data center sector is moving from voluntary energy standards to mandatory compliance. Although standards like ANSI/ASHRAE Standard 90.4 are voluntary frameworks, legal jurisdictions are increasingly adopting them into law, and new regulations requiring sustainability reporting are already passed or pending worldwide. CFD models are used to verify that a proposed design will meet the performance targets of standards like ASHRAE 90.4 and that all equipment will operate within recommended thermal guidelines (e.g., A1-A4 classes) to improve longevity and uptime. [2]

Thermal Storage: System-level simulations are used to model thermal storage tanks (chilled water) to ensure they can provide a sufficient buffer of cooling during a "thermal ride-through" event or power outage. This is critical for data center resiliency.

Designing for Waste Heat Recovery:

CFD helps design systems that can capture the waste heat generated by servers and reuse it, turning an operational cost into a potential asset.

Improving Power Usage Effectiveness (PUE):

While ensuring thermal reliability is paramount, optimizing energy efficiency remains a critical goal. Power Usage Effectiveness (PUE) is the standard metric, calculated by dividing total facility power by the IT equipment power (a perfect score is 1.0). Historically, poor airflow management (like hot air recirculation) was a major contributor to high PUE. Today, while significant PUE improvements often come from selecting efficient equipment (chillers, UPS) and system strategies (like free cooling or raising operating temperatures), CFD plays a crucial enabling role:

Validating Efficiency Strategies: CFD confirms that strategies like using economizers or raising server inlet temperatures (within ASHRAE guidelines) won't create hot spots, allowing you to maximize their PUE benefits safely.

Quantifying Airflow Management Impact: CFD precisely models the negative impact of recirculation and bypass air on cooling load. Eliminating these issues through CFD-informed adjustments directly reduces cooling energy waste and lowers PUE.

Optimizing Component Performance: CFD helps quantify the real-world efficiency gains of components like variable speed fan drives by simulating their operation under actual facility conditions and part-load scenarios.

What is a Data Center Digital Twin?

A data center digital twin is a comprehensive, system-level virtual model that goes beyond standard CFD. It integrates 3D CFD models (often as fast-running Reduced Order Models, or ROMs) with 1D models of the electrical grid, power distribution, and control logic to create a holistic simulation of the entire facility's operation.

The primary benefit of a digital twin is virtual commissioning. By connecting the digital twin to the actual PLC control software, engineers can test how the data center will respond to different scenarios (like a power failure) and debug the control logic long before the physical facility is built. This saves significant time and cost during on-site commissioning and prevents late-stage errors.

Your data center must accommodate growth without overbuilding. CFD is your crystal ball:

Model "what-if" scenarios: How will adding high-density racks (20kW+) in specific locations affect overall cooling?

Simulate the thermal impact of upcoming hardware refreshes (e.g., transitioning from 2U to 1U servers) to plan cooling upgrades.

Assess how changes in rack layout or aisle configuration can extend cooling capacity, delaying costly infrastructure expansions.

Frequently Asked Questions (FAQ) about Data Center CFD

How does CFD help reduce PUE?

CFD helps reduce PUE by identifying cooling inefficiencies. By simulating airflow, a CFD analysis can pinpoint where cold air is being wasted (bypass), where hot air is mixing with cold air (recirculation), or which servers are not receiving enough cooling. Fixing these issues reduces the workload on fans and chillers, lowering their energy consumption and thereby improving the overall PUE. [9]

What's the main difference between a CFD model and a Digital Twin?

A CFD model typically focuses on one physics domain, like airflow and heat transfer (3D). A Digital Twin is a more comprehensive, multi-physics model that connects the CFD results with other system models, such as the electrical power distribution and the control system (1D). The digital twin simulates how all these systems interact together over time.

Is CFD useful for designing liquid and immersion cooling systems?

Yes, it is essential. For Direct Liquid Cooling (DLC), CFD is used to design the microchannels in cold plates to ensure even heat removal from chips. For immersion cooling, CFD simulates the complex two-phase flow (liquid boiling into vapor) to ensure the system can handle extreme heat loads without failure.

How long does a data center CFD simulation take?

The time required for a CFD simulation can range from a few hours for a simple component analysis to several days for a complex, transient model of an entire data hall. The exact time depends on the model's complexity, the level of detail required, and the available computing power.

However, the key is the return on that time investment. A simulation that runs for 24-48 hours can provide insights that prevent a multi-week delay during physical testing or uncover a critical design flaw that could cost hundreds of thousands of dollars to fix post-construction. It’s about investing hours upfront to save weeks and significant capital down the line.

What is the role of Artificial Intelligence (AI) in data center management?

AI is increasingly being used to improve data center operations. A 2024 survey found that operators use AI primarily to increase facility efficiency (58%) and lower the risk of human error (55%). However, the same survey noted that trust in AI to make critical operational decisions has declined for the third consecutive year, suggesting a healthy skepticism remains in the industry as this technology matures.

About Resolved Analytics & How We Can Help

Resolved Analytics was founded by Professional Engineers, including Co-Founders and Managing Partners, Caleb and Stewart,, both PEs with two decades of experience in fluid dynamics. We specialize in helping companies move beyond traditional, siloed engineering methods.

We believe that by using advanced simulation like Computational Fluid Dynamics (CFD), engineering teams can validate designs earlier, reduce reliance on costly physical prototypes, and bring more innovative products to market faster. Our expertise lies in applying this modern, digital approach to solve complex thermal challenges, with a special focus on data center optimization

Take the Next Step in Data Center Optimization

Ready to reduce your PUE, enhance resiliency, and de-risk your next project? Our team has set aside time for a consultation to dig deeper into what a modern, simulation-driven approach could look like for your business.

Contact us today to learn how our CFD and digital twin services can help you achieve your data center's performance and sustainability goals.

Citations

[2] Data Centers and Their Energy Consumption: Frequently Asked Questions

[4] Powering AI data centers: Meeting North America's electrical and energy needs

[5] Siemens SW Facebook achieves thermal efficiency White Paper

[7] Siemens SW Simcenter Divide and Conquer Power Savings from Server to Datacenter White Paper

[8] Enhancing energy efficiency and sustainability of data centers