SELECTIVE CATALYTIC REDUCTION (SCR) DESIGN AND OPTIMIZATION

As the need to mitigate the impact of climate change from human activity becomes increasingly important in the modern world, SCR remains one of the primary methods of reducing exhaust pollutants.

As the need to mitigate the impact of climate change from human activity becomes increasingly important in the modern world, Selective Catalytic Reduction (SCR) remains one of the primary methods of reducing exhaust pollutants. SCR systems are now commonplace in the exhaust flow of most combustion engines and have been applied to systems of all sizes from automobiles and diesel trucks to marine vessels and power plants.

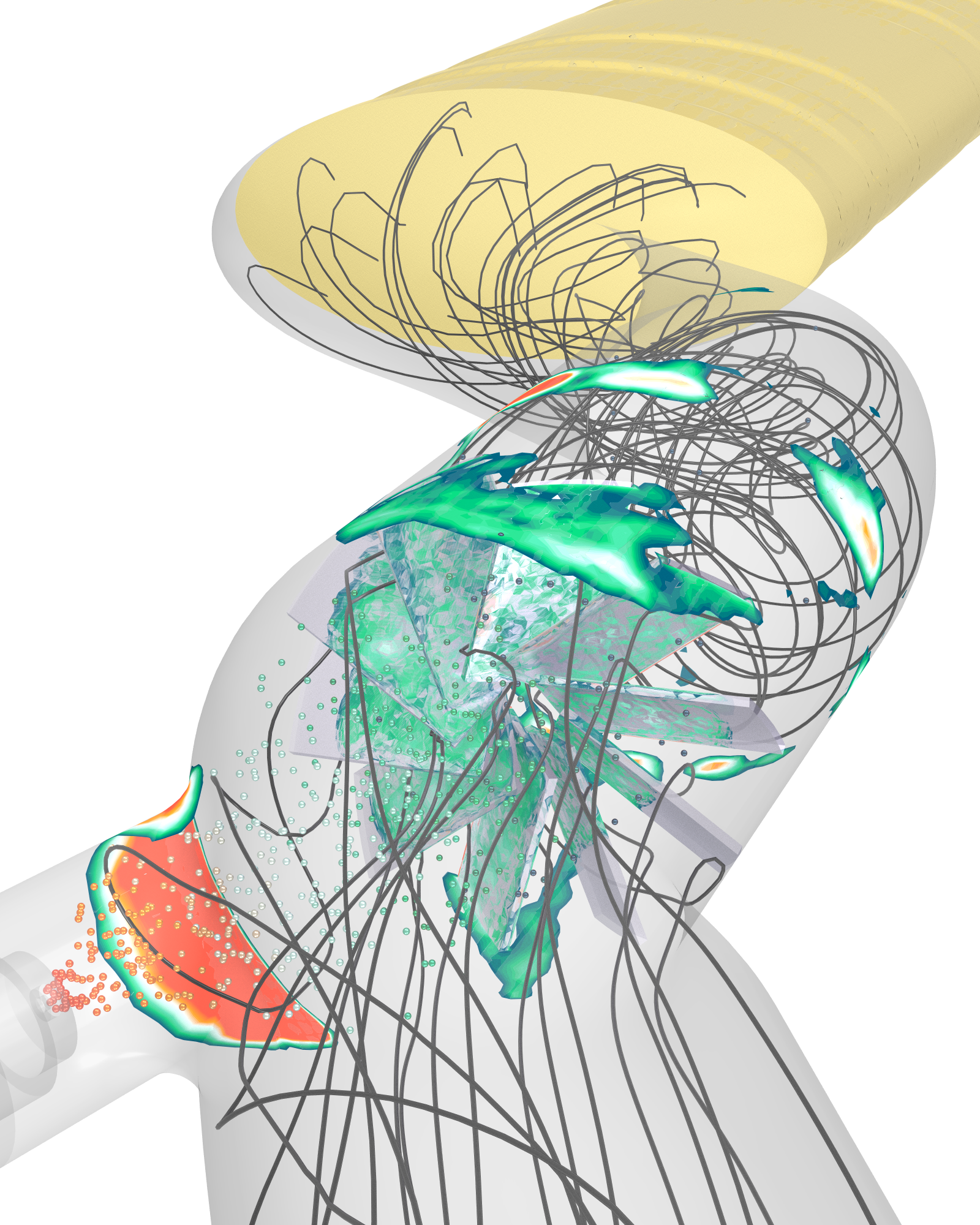

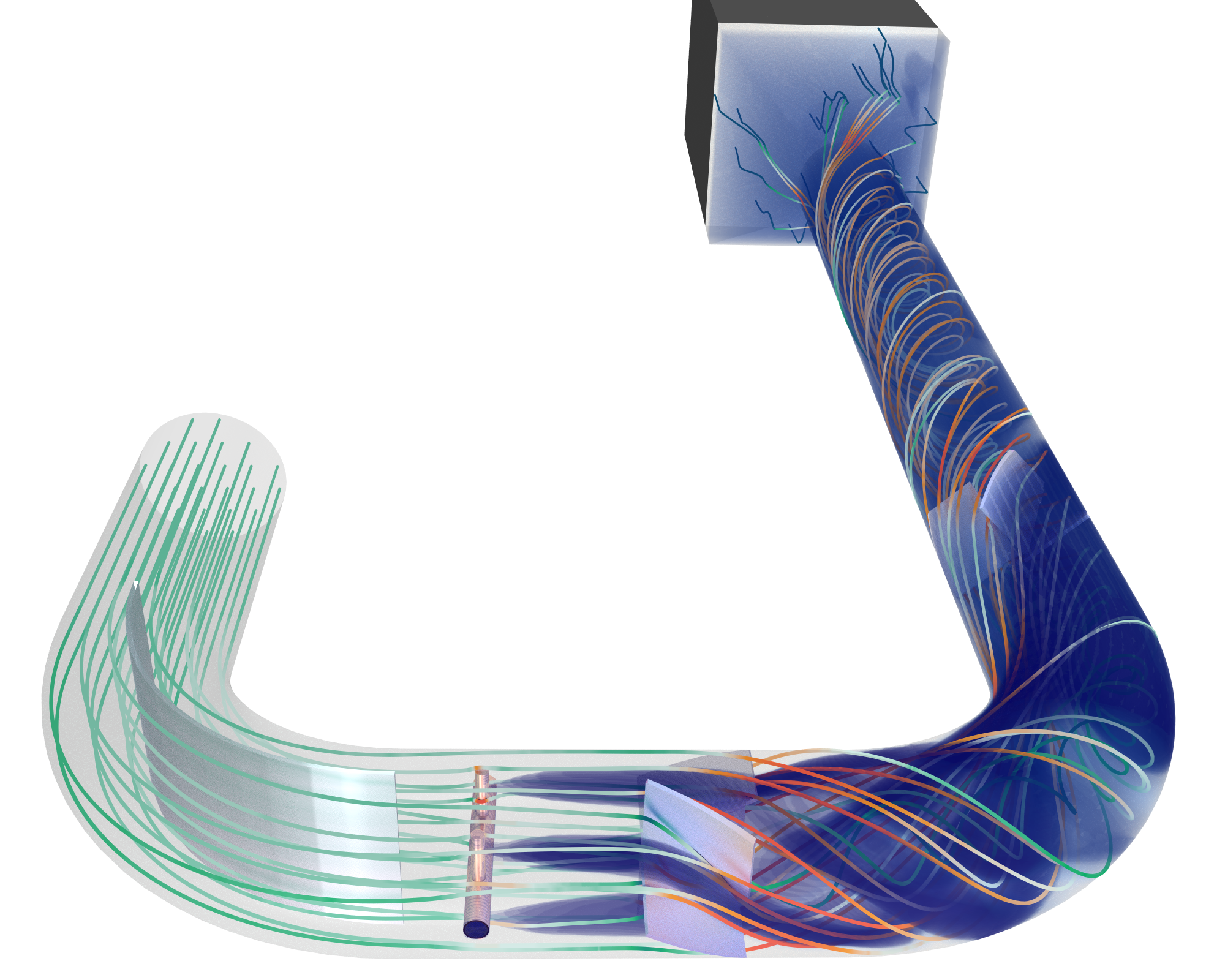

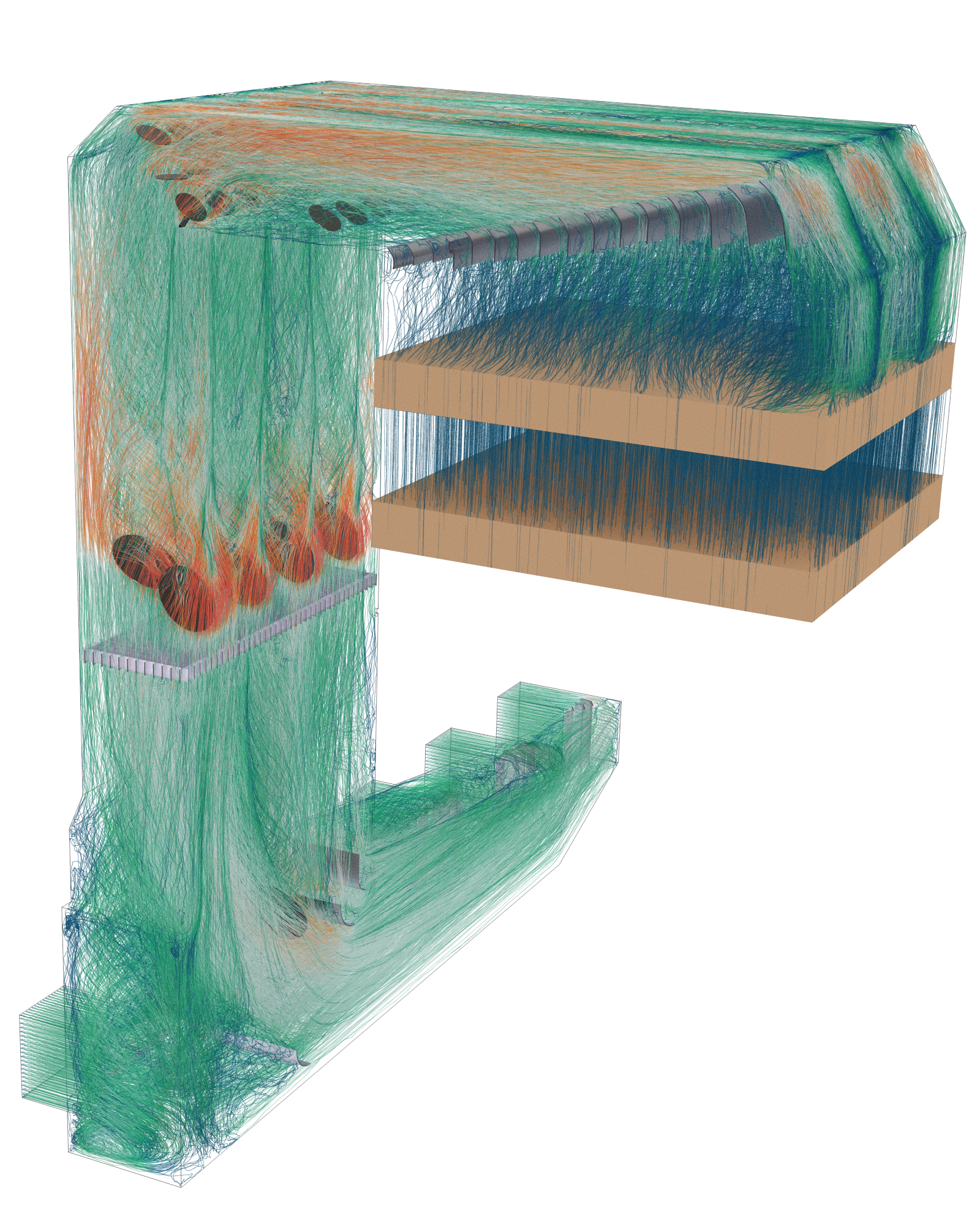

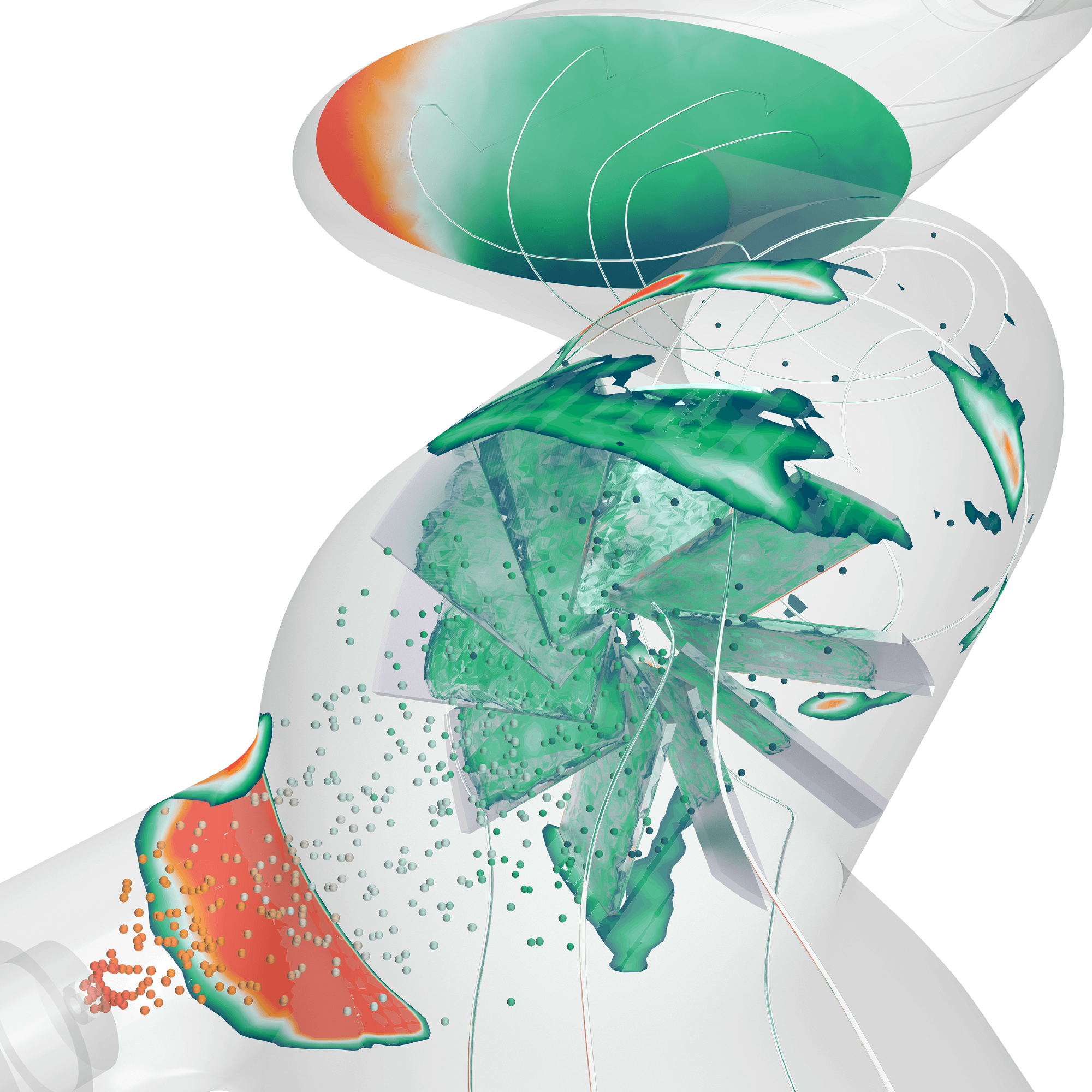

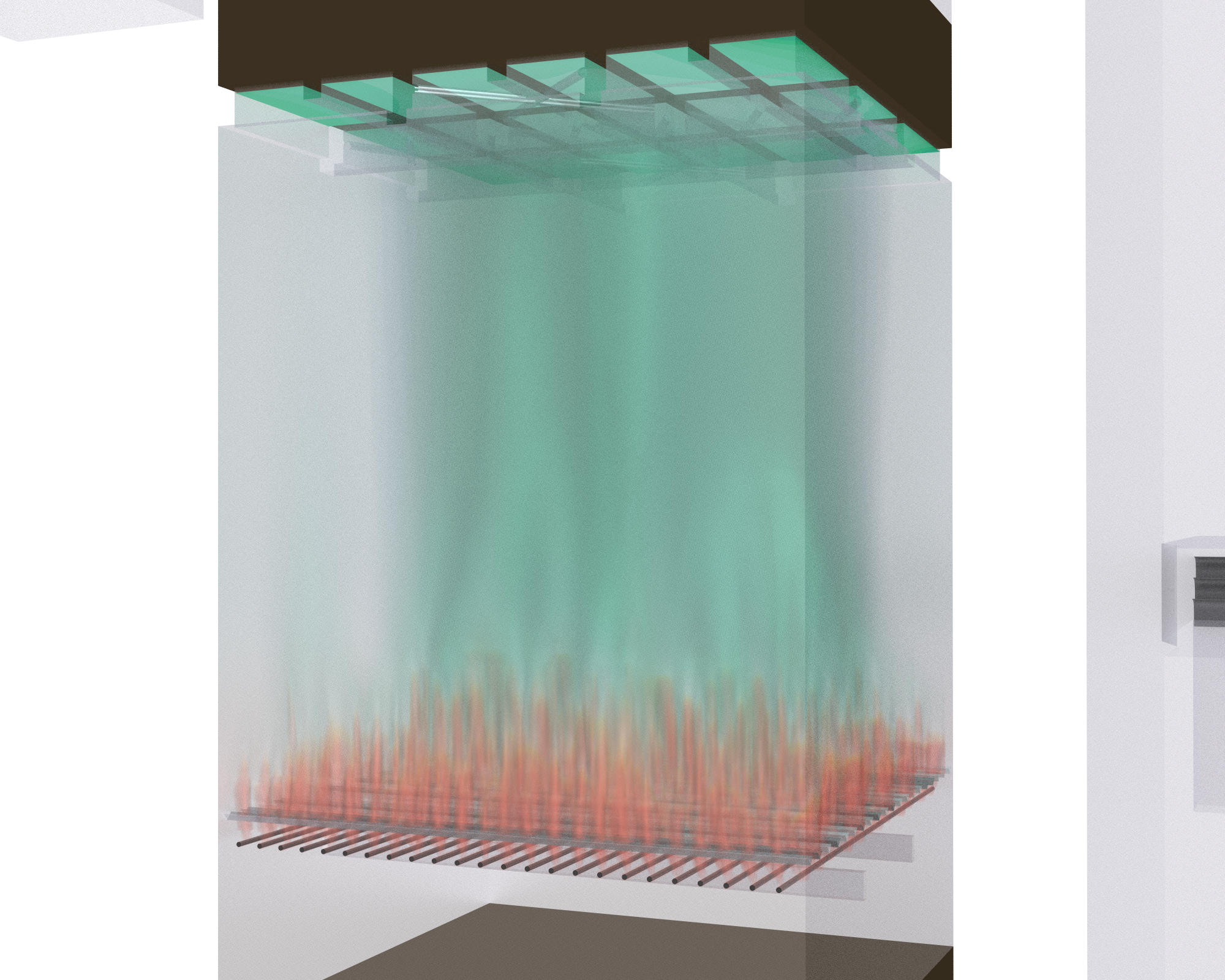

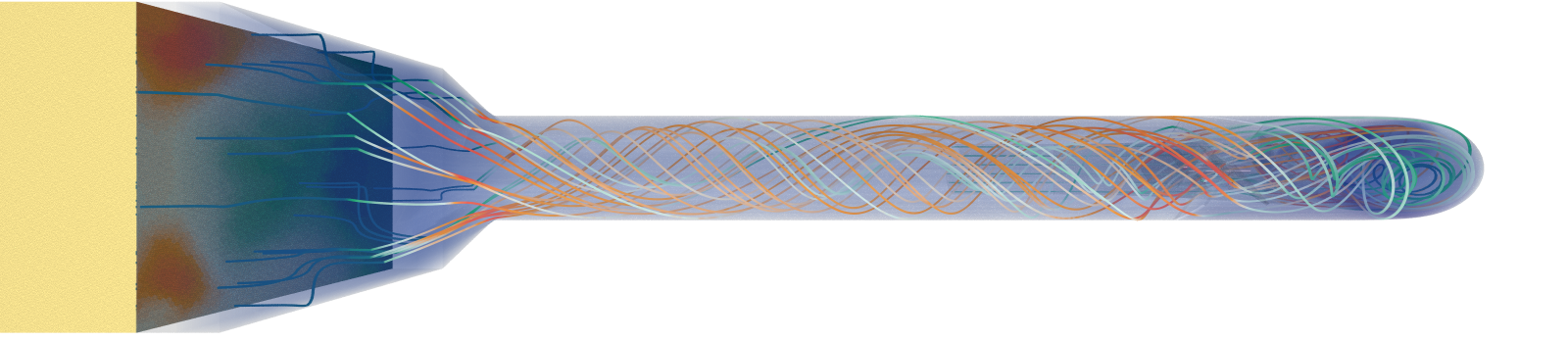

SCR systems use the combination of a catalyst (a ceramic block that facilities the reactions) and a reagent (typically ammonia or urea) to covert NOx emissions from combustion processes into a harmless stream of nitrogen and water vapor. The reagent is typically injected upstream of the catalyst via a pipe manifold system or liquid injectors and is then given time to mix across the flue gas stream before impacting the catalyst.

Fluid dynamics plays a primary role in the design and optimization of SCR systems. The most critical factor to SCR performance is the uniformity of the reagent across the catalyst block. If the reagent is too low in a specific region, no NOx will be reduced; and if it is too high, the SCR will exhaust large amounts of ammonia, known as ammonia slip. Thus, a well-designed reagent injection system is paramount to the performance of any SCR system.

The second largest factor to SCR performance is the flow distribution into the catalyst. Specifically, the pollutant laden exhaust flow needs to enter the catalyst surface evenly to reduce the maximum possible NOx. If the flow is biased toward one side, then the catalyst cannot remove the NOx, and this portion of the catalyst is effectively wasted.

CFD analysis allows for the visualization of a detailed 3D, full-flow field within the entire scope of the SCR system. This is something that cannot be done in the field due to the limited number of measurements and the measurement locations. This high fidelity allows for unparalleled measurement and analysis of the flow and reagent distribution entering the catalyst, and optimization methods that improve the flow and ammonia uniformity can be quickly and easily implemented.

The partners at Resolved Analytics have decades of experience designing, optimizing, and troubleshooting the flows within SCRs and have close relationships with most major de-NOx catalyst manufacturers. We specialize in the design of reagent injection systems, mixers, and flow distribution devices for both new and retrofit applications. Whether your issue is related to high ammonia slip, poor NOx reduction, or excessive pressure drop, you could not be in better hands, ensuring that poor SCR performance can become a thing of the past.

Design, Optimize, and Troubleshoot Your SCR System with Computational Fluid Dynamics