Simcenter STAR-CCM+ 2510: A Focus on Speed

Major Performance Gains in 2510

The Simcenter STAR-CCM+ 2510 release delivers massive performance gains, including up to 10x faster structural mechanics, 4.8x faster GPU-native simulations, and a 10x faster automated turbomachinery workflow. This update also introduces powerful new SPH capabilities, advanced battery modeling, and major speed-ups in meshing and geometry handling.

⭐ Top Features in Version 2510

This release is one of the biggest performance updates in recent history, delivering massive speed-ups across every stage of the simulation workflow.

✅Massive Gains for Structure Mechanics: Run simulations with strong non-linearities like buckling up to 10x faster with the new Time-Step Recovery feature. Model thin structures (like sheet metal) with Structural Shells for a >10x speed-up over standard solid meshes.

✅Blazing-Fast GPU Acceleration: Get results faster with GPU-native solvers, delivering up to 4.8x speed-ups in aero simulations, 5x faster SPH simulations, and 3x faster DEM particle injection.

✅Smarter, Faster Meshing: Slash your preprocessing time with a new Parallel Surface Wrapper (up to 82% faster than legacy) and an incredibly fast discrete proximity checker that is 30-100x faster than the CAD-based method.

✅Powerful New Physics & Workflows:

Turbomachinery: A new automated workflow goes from blade data to a run-ready sim file in under 5 minutes—a 10x speed-up over the previous tool.

Smoothed-Particle Hydrodynamics (SPH): Major new capabilities have been added, including adaptive particle refinement, multi-body motion with solid-to-solid contact (DFBI Meshfree), and one-way fluid-structure coupling.

Batteries: Model battery thermal runaway with higher predictability using the new Arrhenius Pseudo Reaction model.

In This Article:

Platform Updates: Going Faster with HPC

Massive GPU Acceleration

Memory Footprint Reduction

Runtime & Interoperability (Teamcenter, FMI)

Data Analysis & Visualization

Geometry and Meshing: Slashing Pre-Processing Time

3D-CAD & Geometry Handling

Meshing Pipeline & Boolean Performance

Surface Wrapper (Phase 2)

Motion & DFBI Updates

Physics Enhancements: New Models & 10x Speed-ups

Flow, Heat Transfer & Adjoint

Multiphase (LMP & DEM)

Reacting Flows & Combustion

Structural Mechanics (Time-Step Recovery & Shells)

Industry Solutions: Tailored Workflows

Acoustics

e-Powertrain & Battery Modeling

In-Cylinder

Smoothed-Particle Hydrodynamics (SPH)

Turbomachinery (New Automated Workflow)

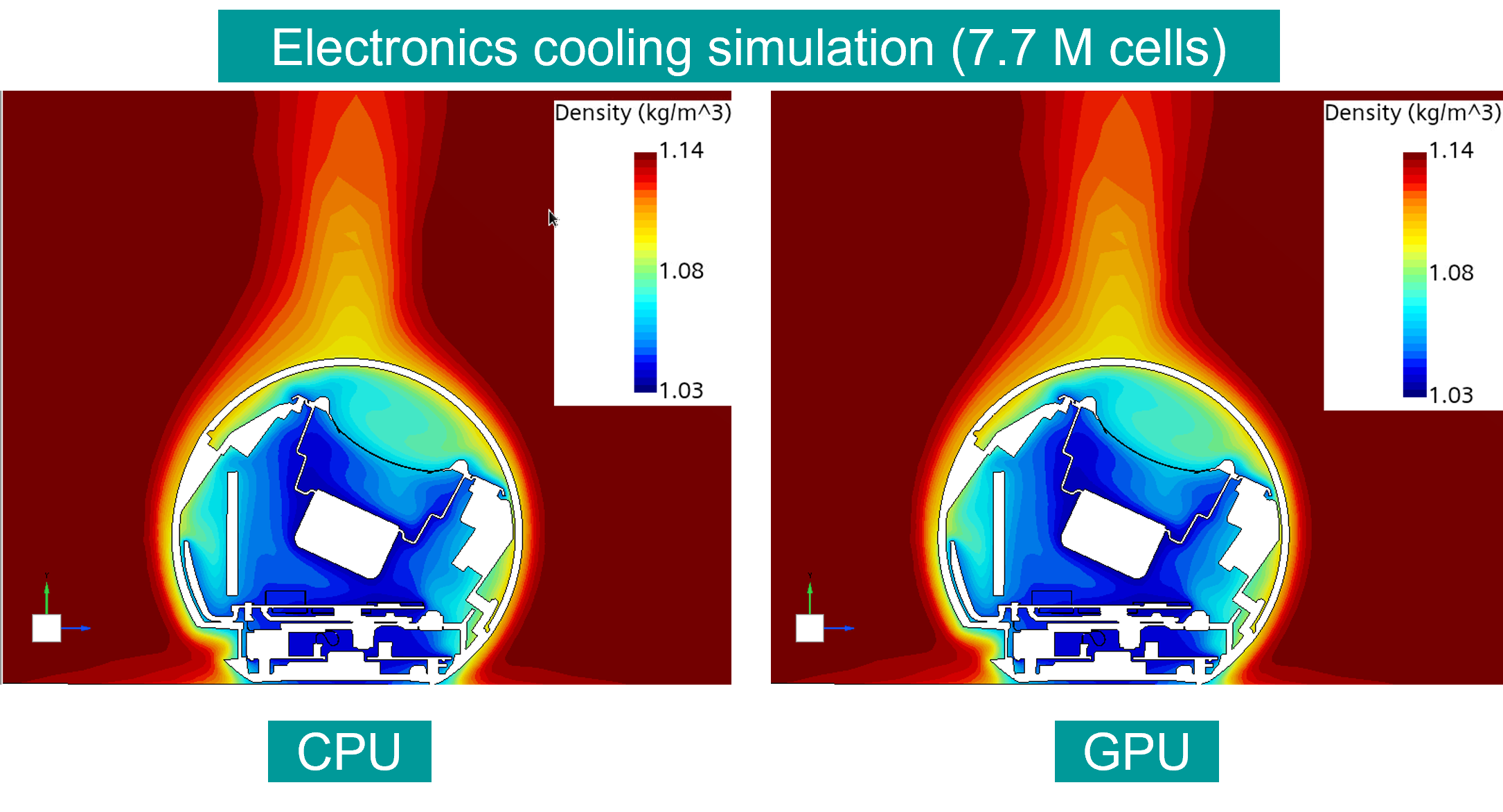

Faster turnaround time for advanced flow and Conjugate Heat Transfer (CHT) simulations with GPU-native Polynomial Density material property method

Faster turnaround times for advanced flow and Conjugate Heat Transfer (CHT) simulations with GPU-native temperature dependent material property methods

Platform

This section covers updates to the software's foundation, including OteramS support, performance enhancements, and data interoperability.

Deployment & OS Updates

Linux:

Added for RHEL 9.6/10.0, Alma 9.6/10.0, Rocky 9.6/10.0, and SLES 15.7.

Retired for RHEL 8.6/8.8, Alma 8.6/8.8, Rocky 8.6/8.8, SLES 15.5, and Open SUSE Leap 15.5.

Windows:

Added for Windows Server 2025.

High-Performance Computing (HPC)

This area focuses heavily on GPU acceleration and memory efficiency.

GPU Acceleration: Faster turn around times

The Random Injector for DEM simulations is up to 3x faster on GPUs. GPU-native material properties can lead to up to a 4.8x speed-up in automotive and aerospace simulations.

GPU-native density properties can achieve up to a 3x speed-up in Vehicle Thermal Management simulations.

The GPU-native radiation solver provides up to a 1.6x speed-up for combustor CHT studies with radiation.

SPH Boundary Integral Method performance is optimized, showing up to a 5x speed-up on a GPU.

GPU acceleration for SPH derived parts is up to 4.7x faster with opened scenes and up to 2 times faster with scenes hidden.

The GPU-accelerated Virtual Disk method for helicopter aerodynamics (14.3 M cells) showed a 2.4x speed-up when comparing 256 CPU cores to 4 NVIDIA A100 cards.

AMD GPU Performance:

Simulations using AMD MI300 series GPUs are up to 3.6x faster in version 2510 compared to 2506.

Memory Footprint Reduction:

Memory usage is reduced by up to 30% through unified memory allocation.

On Windows, memory savings of up to 18% are achieved with MPI-3 shared memory.

Runtime & Interoperability

Cluster Submission: A new feature generates scripts to simplify launching jobs on clusters supporting schedulers like SLURM, LSF, and Torque.

Teamcenter: Integration of Simcenter STAR-CCM+ 2510 is now certified for Teamcenter version 2506, with multi-version support allowing asynchronous upgrades.

FMU: Implicit coupling is now available for Functional Mockup Interface (FMI), which improves the accuracy and stability of highly dynamic coupled systems.

Co-simulation: A new mutual termination handling feature saves HPC resources by allowing coupled applications to send and receive a termination notice.

CAE Versions: Support has been updated for CGNS 4.5.0.

Interactively visualize 3D transient data with Resampled Volume support for Solution Histories

Whatever it is, the way you tell your story online can make all the difference.

Understand results better with volume rendered animation

Whatever it is, the way you tell your story online can make all the difference.

Design Manager & Data Analysis

Design Manager: Now supports photo-realistic Studio Scenes and allows copy-and-paste between its Design Table and Microsoft Excel.

Solution Histories: This feature now supports Resampled Volume for visualizing transient data, reducing file size by up to 5x compared to storing the full mesh and solution.

Data Export: Reports can now be exported to a .csv file via the Tabular Summary feature.

Visualization:

Animations are now supported in the Simcenter Web Viewer.

The interactive frame rate in Studio Scene is 3.5x higher than in version 2506.

Removal Notices:

The standalone Simcenter STAR-CCM+ Viewer will be removed starting in version 2606 and replaced with a downloadable Web Viewer.

Block-Mapped Coordinate Systems will be removed starting in version 2606

Accelerate design workflows by converting revolved and planar meshed faces into precise BRep sheet bodies. Creates precise geometric representations from mesh data. Enables downstream CAD operations without original geometry. Reduces dependency on source CAD files. Streamlines reverse engineering workflows

Geometry and Meshing

This section details updates to CAD handling, geometry preparation, and mesh generation.

CAD & 3D-CAD

There are many updates here, and most (but not all) of them are listed below:

Automated metadata transfer between CATIA and Simcenter STAR-CCM+.

CAD Interoperability: CAD import is updated for new versions, including NX2506, CATIA V5-6R2024, and JT up to 10.7.1.

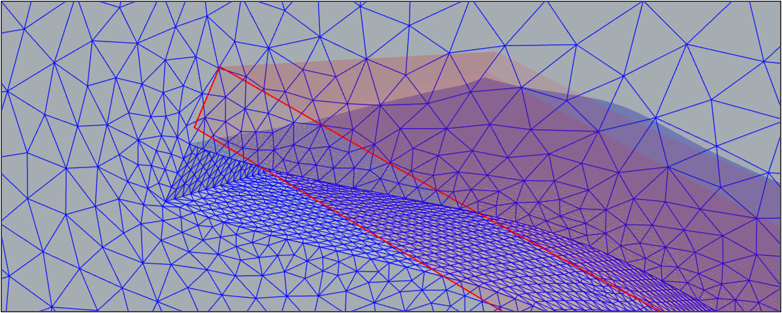

Proximity Checker: A new discrete-geometry-based face proximity checker is 30 to 100x faster than the CAD-based method, making it practical for large assemblies.

Convert revolved and planar meshed faces into Brep sheet bodies.

Quickly create reference axes from mesh geometry without needing the original CAD model.

Improved Design Parameter organization.

Optimized contact detection (30-100x faster search times).

Pattern instance skipping in Linear and Circular Pattern features.

More flexibility in updating Parts that are linked to 3D-CAD.

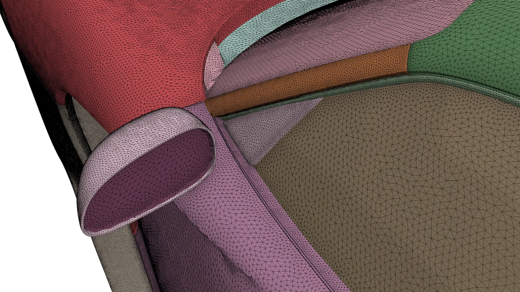

Meshing Pipeline & Operations

Performance:

Fast, automated and pipelineable workflow for creating coordinate systems

The discrete Subtract Boolean operation is up to 2.7x faster with improved scalability. One VTM geometry case shows a 62% reduction in wall time, and an external aero case shows a 54% reduction.

The discrete Imprint operation is up to 2x faster. A non-conformal battery pack case shows a 50% time reduction, and a conformal industrial case shows an 11% reduction.

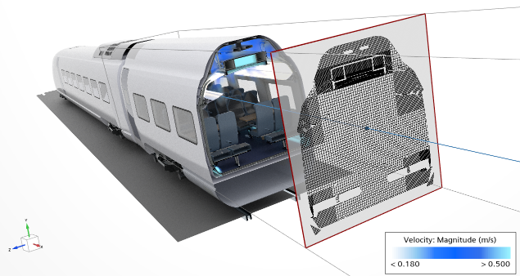

Surface Wrapper: The Parallel Surface Wrapper (Phase 2) further improves performance, offering up to an 82% time reduction compared to the legacy wrapper and up to a 49% reduction compared to the Phase 1 wrapper from version 2506. Speedup compared to the legacy wrapper ranges from 2.4 to 5.6 across various test cases.

Volume Mesher: The polyhedral volume mesher is up to 60% faster at high core counts when used with quad-dominant surface meshes.

Motion, Overset and Adaptive Mesh Refinement

DFBI Rotational Driver: Improved modeling of rotating components under dynamic conditions

Virtual Body Updates: Improved simulation accuracy by maintaining exact locations of sharp corners

Physics

This section describes new models and enhancements across a wide range of physics simulations.

Correct mesh deformation with no pierced faces

Support symmetry and periodic boundary conditions for the filtered surface sensitivity

Flow, Adjoint, and Heat Transfer

Natural Convection: The coupled flow solver converges faster for natural convection flows by accounting for gravity body forces.

Easier troubleshooting of assigned material properties

Adjoint Topology Optimization: A new dynamic penalty update algorithm leads to up to 3x faster and more stable optimization by reducing user intervention.

Accurate sensitivity and deformation fields near symmetry and periodic boundaries

Thermal Comfort: Thermoregulation and comfort index models (e.g., Fiala, Berkeley) are now compatible with unsteady and multi-time scale analyses, enabling transient studies like cabin cool-down cycles.

Multiphase (LMP & DEM)

Wall-Bound Droplets:

The solution for Lagrangian wall-bound phases is up to 2x faster due to algorithmic improvements. A new model allows for the coalescence of wall-bound droplets.

Improved accuracy of simulating solid particle flows with the Particle Rotation model

Faster simulations and improved user experience with smaller track files

DEM & Fluid Film:

DEM for arbitrary shape particles is now compatible with the Fluid Film model, extending the scope to applications like tablet coating and battery runaway.

Faster and less error-prone input of DEM multiphase interactions with the Template Phase Interaction option

Custom initial shapes of injected fibers

Reacting Flows & Structure Mechanics

Combustion: The Complex Chemistry Turbulent Flame Speed Closure (CC-TFC) model is up to 45% faster due to algorithmic improvements, with the largest benefit seen in mechanisms with more species/reactions.Easier application of TFS correlations for In-Cylinder

Electrochemistry and Electromagnetics: Faster time to solution for simulations leveraging electrodynamic potential (EDP) with Adaptive Mesh Refinement (AMR) compatibility. Improved fidelity and user experience for higher order EMAG simulations.

Structure Mechanics:

A new Time-Step Recovery feature provides a 10x speed-up and improved robustness for simulations with strong non-linearities like buckling.

Structural Shells essentials offer a >10x speed-up for modeling thin structures by allowing for coarser meshes with similar accuracy to fine solid meshes.

Accurate material modelling with time- and rate-sensitive plasticity.

Finite Element Rheology: Model a wider range of manufacturing applications with moving parts.

Simulate complex multiphase systems involving coexisting liquid films and arbitrary shape particles with DEM and Fluid Film now compatible

Industry Solutions

This section details features tailored for specific industry applications.

One of the key tools for preparing the geometry for meshing in Simcenter STAR-CCM+ is the Surface Wrapper. The Surface Wrapper can take any arbitrarily complex CAD or tessellated part and generate a watertight, manifold surface. It works by effectively “shrink-wrapping” a high-quality triangulated surface mesh onto the discretized geometry. One of its key strengths is the ability to accurately preserve geometric features such as sharp edges and corners.

Acoustics

On-the-Fly Discrete Fourier Transforms allow for earlier identification of noise sources on volumes and surfaces without saving large files. The Lilley and LEE Sources models will be removed starting in version 2602.

E-Powertrain

The pack thermal runaway tool now includes an Arrhenius Pseudo Reaction model for more predictable cell self-heating simulations.

A new Cathode Active Material Dissolution aging model has been added to the 3D Cell Design tool.

Enlarged spectrum of e-machine types with radial flux machine support.

In-Cylinder

Enhanced accuracy through temperature-dependent thermal conductivity for gaseous species.

Faster sector modeling pre-processing

Two new features: Multi-cylinder-compatible Engine Parts Creation panel and Valves as children of associated cylinder

Smoothed-Particle Hydrodynamics (SPH)

New Capabilities: This release introduces several new features for SPH, including adaptive particle refinement, DFBI Meshfree Multi Body Motion to model contact between solids, support for outlet boundary conditions, and one-way fluid-structure co-simulation with the FEA solver.

Turbomachinery

Automated Workflow: A new, fully integrated Turbomachinery Import Workflow automates the process from blade curve data to a fully set up simulation file in less than 5 minutes. This workflow is up to 10 times faster for import and CAD generation compared to the previous TAW APT tool.

Meshing Fidelity: The Turbomachinery Mesh generator now includes a CAD projection option to increase geometry fidelity without needing a separate surface mesh generation step.

Simcenter STAR-CCM+ continues to advance its SPH solver with significant enhancements, including local particle refinement, a streamlined workflow for planetary gears, and additional data analysis capabilities, as well as robust GPU acceleration.

Try Simcenter STAR-CCM+ 2510 Today

📌Want to see it in action? Explore the full release notes or contact us for more details. Purchase STAR-CCM+ now directly online!

💡 Looking for more CFD insights? Check out our latest case studies and CFD Insights blog articles.