Technological Advances with Fluid Dynamics

Fluid Dynamic Innovations that Drive Technologies

Innovation is the engine that drives technological development, and fluid dynamics is the fuel that feeds it. By studying the behavior of fluids, we have been able to make significant strides in transportation, energy, and consumer products. But what is fluid dynamics, and how has it changed the world? In this article, we will explore the historical significance of fluid dynamics in technology and take a closer look at how it continues to drive innovation today.

How Fluid Dynamics is Accelerating the Pace of Technological Progress

From the days of the Wright Brothers to modern jet planes, fluid dynamics has played a fundamental role in aviation. The Wright Brothers were chiefly “experimentalists” but their very innovative work in aviation was fueled by an understanding of the principles of theoretical fluid dynamics that they had gained by requesting various publications by other aeronautical pioneers from the Smithsonian Institute. As demonstrated by their example, understanding how air flows over a wing can help engineers design a more efficient and stable aircraft. Yet, aviation is just one example of how fluid dynamics is being applied in modern technology. In industries such as energy, transportation, and consumer products, researchers are leveraging the principles of fluid dynamics to deliver more efficient, cost-effective, and sustainable solutions.

For instance, in the automotive industry, designers are relying on fluid dynamics to improve fuel efficiency and reduce emissions. By understanding how air moves around a car, engineers can optimize its shape to produce less resistance, thereby reducing fuel consumption. Formula 1 race cars, for example, are designed to be aerodynamic and create as little drag as possible, which can ultimately lead to faster lap times. In this article, they discuss how fluid dynamics, specifically Computational Fluid Dynamics (CFD) is not only used to greatly improve the fuel efficiency, but can now be used for much more.

(Pressure Distribution on Frame of F1 Race Car – As predicted by CFD Simulation)

Fluid dynamics is also revolutionizing the way we create energy. Wind turbines are one example of how fluid dynamics is being used to generate power. These turbines use the power of the wind to turn blades, which in turn generate electricity. By designing turbines that are as efficient as possible, we can create more energy while using fewer turbines, reducing materials and maintenance costs.

(Aerial drone tour of the 659 MW Walney Extension offshore wind farm in the Irish Sea – courtesy of The Guardian on YouTube)

Fluid dynamics is also making a significant impact in the field of marine engineering. Understanding how water flows around a ship can help engineers design more efficient and faster vessels. By optimizing the shape of a ship's hull, engineers can reduce drag, which can lead to significant fuel savings. Additionally, researchers are using fluid dynamics to study wave patterns, which can help predict and prevent shipwrecks.

Fluid dynamics is also being used in the development of consumer products. For example, designers of sports equipment such as golf balls and tennis rackets use fluid dynamics to optimize the shape and weight of their products. This can help athletes achieve better performance and results. Additionally, fluid dynamics is being used in the development of household appliances such as vacuum cleaners and air purifiers. By understanding how air moves through these products, engineers can design more efficient and effective devices.

(A golf club head moving through air – fluid dynamics is critical to the performance of many such sporting goods – courtesy Business Insider)

Finally, fluid dynamics is playing a crucial role in the development of new medical technologies. Researchers are using fluid dynamics to study blood flow and the movement of fluids through the body. This understanding is helping to develop new treatments and therapies for a range of medical conditions from heart disease to cancer.

Fluid dynamics is a critical field of study that is accelerating the pace of technological progress. From aviation to energy, transportation to consumer products, and even medical technologies, fluid dynamics is being used to deliver more efficient, cost-effective, and sustainable solutions. As our understanding of fluid dynamics continues to advance, we can expect to see even more exciting applications in the years to come.

Historically Important Technologies Made Possible through Fluids Engineering

Fluid dynamics has been at the heart of technological development for centuries. In fact, we’ve written about the top ten fluid technologies previously. One of the earliest examples of fluid dynamics in action was the steam engine invented by James Watt in the eighteenth century. Using the power of steam to produce rotary motion, Watt's engine was a significant step forward in energy production and helped to drive the Industrial Revolution.

However, the steam engine was not the only technology that benefited from fluid engineering. Another example is the development of hydraulic power. Using the flow of liquids to create pressure, hydraulic systems are used to perform work, and therefore energy. Hydraulic systems are used in everything from car brakes to cranes and have been instrumental in advancing the manufacturing industry.

Fluid dynamics has also been essential in the development of modern medicine. For example, ultrasound technology, which uses sound waves to create images of the inside of the body, relies on our understanding of how sound waves travel through fluids. Similarly, the study of blood flow and circulation has been critical in the development of treatments for heart disease and other cardiovascular conditions.

(Visualization of the fluid dynamics of the cardiac cycle – systolic contractions pump oxygen rich blood to the arteries while diastolic expansion suctions deoxygenated blood from the veins – Courtesy of Visible Body)

Finally, fluid dynamics has played an important role in the development of renewable energy technologies. Using this knowledge of how air flows over a surface, we are able to harness energy from wind and waves, manipulating the earth’s natural effects to something greatly beneficial to the world.

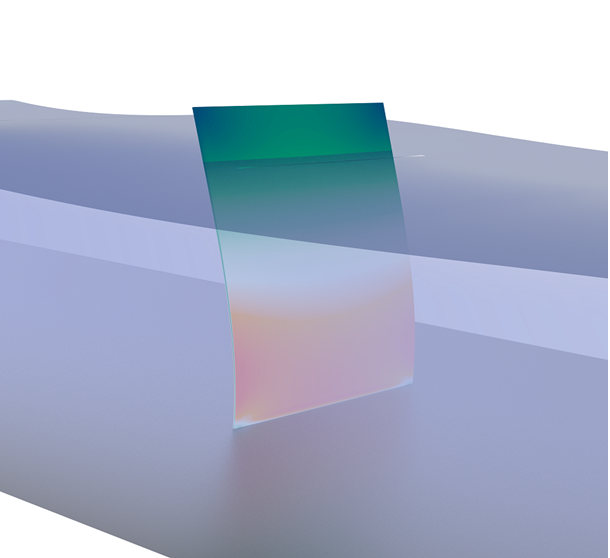

(Visualization of Wave Energy Collection Device simulated in Computational Fluid Dynamics, with colors representing the magnitude of mechanical stress)

Propulsion and Lift

As we’ve discussed, the Wright brothers used their knowledge of fluid dynamics to design wings that could generate lift. By studying the way air flows over a surface, they were able to create a heavier than air aircraft that could stay aloft for extended periods of time, later developing into the modern airplanes we see today. When they first took to the skies in the early twentieth century, they did so with the help of a propeller. This simple device converts rotary motion into forward motion by moving air backwards. The principles of fluid dynamics that underpin the operation of a propeller are the same as those used to design the rocket engines that propelled astronauts to the moon.

(An image of the Wright Brothers inaugural flight with Orville at the Controls and Wilbur watching from the ground )

The development of rocket engines was a crucial element in the success of the Apollo missions. These engines used a process called combustion to generate the high levels of thrust required to break free from the Earth's gravitational pull. The fuel and oxidizer were combined and ignited, producing a stream of hot gases that was expelled out of the engine's nozzle at high speeds. This expelled gas created an equal and opposite reaction, propelling the rocket forward. NASA was one of the greatest developers of computational fluid dynamics technology that today allows us to simulate complex fluid dynamics behaviors on modern computers, as that shown below, which contained over 555 million cells, required over 500,000 timesteps, and required 5 weeks of computing time on over 4,000 Intel Xeon Skylake cores on Electra Supercomputer at NASA.

(CFD Simulation of Rocket Launch at the Kennedy Space Center in order to evaluate Main Flame Detector design – Courtesy of NASA)

Another factor that makes flight possible is lift. To create lift, an aircraft's wings need to generate an upward force that is greater than its weight. Understanding how air flows over wings is essential to designing aircraft that can achieve sustained, controlled flight.

The shape and size of an aircraft's wings are crucial to its ability to generate lift. The curvature of the wing's upper surface causes air to flow faster over it than it does over the flatter lower surface, creating a difference in air pressure that generates lift. By manipulating the shape and size of wings, researchers can create lift while minimizing drag, enabling planes to fly farther, faster, and more efficiently than ever before.

(CFD Simulation of Transonic Truss-Braced Wing Concept, with airflow colored by Mach Number – Courtesy NASA)

Researchers have also developed a range of other techniques to enhance lift and reduce drag. One such method is the use of winglets, which are small, upturned structures on the tips of an aircraft's wings. These winglets reduce the amount of drag created by the wingtip vortices that form as air flows around the wing.

In addition to wings, other factors that affect an aircraft's ability to generate lift include its weight and the density of the air. To achieve lift, an aircraft needs to be light enough to be lifted by the air, and the air needs to be dense enough to provide enough upward force to counteract the aircraft's weight.

Overall, the principles of propulsion and lift are essential to the development of aviation and space exploration. From the Wright Brothers' first flight to the Apollo missions and beyond, researchers have continued to refine and improve these principles by utilizing fluid dynamics, enabling us to travel farther and explore more than ever before.

Energy Efficiency

Energy efficiency is a top priority for many industries, from automotive to marine. With the increasing focus on sustainability and reducing carbon emissions, companies are looking for ways to improve their energy efficiency and reduce their impact on the environment. One way to achieve this is by applying the principles of fluid dynamics, which can help to create more efficient, streamlined designs that reduce fuel consumption and cut costs.

Cruise liners are giant, complex vessels that require huge amounts of energy to move through the water. These ships are often used for long voyages, and as such, fuel consumption can be a significant cost for cruise companies. By using advanced computational modeling, engineers can optimize the design of the hull and propulsion systems to reduce fuel consumption and increase efficiency. This can include designing a hull shape that reduces drag and improves the flow of water around the ship, as well as using advanced propulsion systems that are more efficient and consume less fuel.

(CFD Simulation of Ocean Cruise Liner)

But it's not just cruise liners that can benefit from these principles. The shipping industry as a whole is responsible for a significant amount of global emissions, and improving the energy efficiency of ships could have a significant impact on reducing these emissions. By implementing these design principles across the industry, we could see a significant reduction in the environmental impact of shipping.

In the world of Formula 1 racing, aerodynamics is key to winning races. By manipulating the airflow around the body of the car, designers can create the downforce necessary to keep the car on the track at high speeds. Additionally, by reducing drag, engineers can improve the speed and handling of the car, ultimately leading to faster lap times. These principles are not just limited to racing cars, however. They can be applied to any vehicle to improve their energy efficiency and reduce their environmental impact.

(Role of Wind Tunnel Testing in F1 Racing – Courtesy of the Aston Martin F1 Team on YouTube)

Advancements in technology have made it easier than ever to apply these principles to various industries. Computational modeling and simulation tools allow engineers to test and optimize designs quickly and efficiently, reducing the time and cost required to develop new, more efficient products. Additionally, the availability of lightweight, high-strength materials has made it possible to design vehicles that are both more efficient and safer.

As the world continues to focus on sustainability and reducing carbon emissions, the importance of energy efficiency will only continue to grow. By applying the principles of fluid dynamics and aerodynamics to various industries, we can create more efficient, streamlined designs that reduce fuel consumption, cut costs, and have a positive impact on the environment.

Modern Heating and Cooling

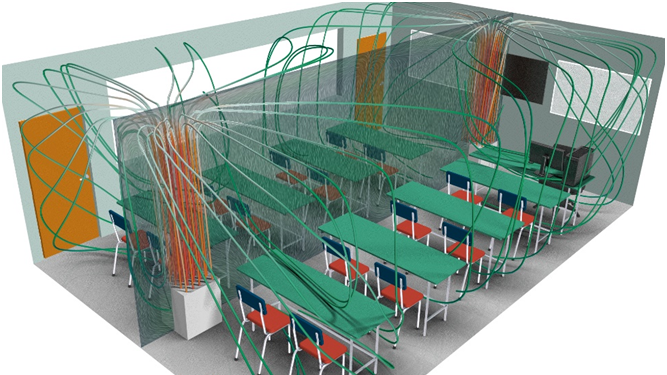

When it comes to HVAC (Heating, Ventilation, and Air-Conditioning) systems, there are a variety of factors that can impact the flow of air throughout a building. These include the size and shape of the space, the number of occupants, and the location of windows and doors. Designers must take all of these factors into account when creating an HVAC system that will keep occupants comfortable.

(CFD Simulation of Air Purifier Placed Centrally in a Classroom)

In addition to optimizing ducts and vents, designers can also use advanced technologies to improve the efficiency of HVAC systems. For example, some systems use sensors to detect temperature and humidity levels in different parts of a building, and then adjust the flow of air accordingly. This can help to ensure that each area of the building is receiving the appropriate amount of heating or cooling.

When it comes to furnaces, fluid dynamics plays a critical role in the combustion process. Engineers must carefully control the flow rate of gases and air to ensure that the fuel is burned efficiently. This not only helps to reduce fuel costs, but also minimizes the amount of harmful emissions released into the environment.

(CFD Simulation of Gas Flow Through a Heat Recovery Steam Generator Downstream of a Natural Gas Turbine with Streamlines Colored by Temperature)

There are a variety of factors that can impact the efficiency of a furnace. For example, the type of fuel being burned, the size of the furnace, and the design of the combustion chamber can all have an impact on how efficiently the furnace operates. By carefully considering these factors and optimizing the design of the furnace, engineers can create systems that are both cost-effective and environmentally friendly.

Pumps, Fans, and Reactors

Many industrial processes rely on fluid dynamics to operate efficiently. For example, chemical reactors rely on the movement of fluids to ensure that reactions proceed correctly. Pumps and fans are also critical components of many industrial processes, from moving liquids within a chemical plant to ventilation systems in factories.

Chemical reactors are used in a wide range of industries, from pharmaceuticals to petrochemicals. These reactors rely on fluid dynamics to ensure that the reactants are thoroughly mixed and that the reaction proceeds at the desired rate. Engineers use a variety of techniques to achieve this, including the use of impellers to create turbulence and the use of baffles to promote mixing.

In addition to reactors, pumps are used extensively in industrial processes to move fluids from one location to another. This can be as simple as moving water from a storage tank to a processing unit, or as complex as pumping highly viscous fluids through a pipeline. Engineers use a variety of pump designs to achieve this, including centrifugal pumps, positive displacement pumps, and axial flow pumps.

Fans are also critical components of many industrial processes, particularly in the field of ventilation. In factories, for example, fans are used to remove hot air and fumes from the production area, ensuring that workers have a safe and comfortable environment. In addition, fans are used in HVAC systems to circulate air and maintain a comfortable temperature in buildings.

By applying the principles of fluid dynamics, engineers can create systems that operate more efficiently, use less energy, and are less subject to mechanical failure. This reduction in downtime and maintenance costs can deliver significant cost savings to businesses and help to drive innovation in materials science, manufacturing, and other fields. Overall, fluid dynamics plays a critical role in industrial process technology. By understanding the principles of fluid flow and applying this knowledge to the design of pumps, fans, and reactors, engineers can create systems that are more efficient, more reliable, and more cost-effective.

Consumer Products

Fluid dynamics is a fascinating field that has a significant impact on our daily lives, particularly in the design of consumer products. From vacuum cleaners to stand mixers, fluid dynamics plays a crucial role in creating machines that are more efficient and powerful.

Vacuum Cleaners

Modern vacuum cleaners use advanced fluid dynamics to create suction, which is essential for removing dirt and debris from carpets and floors. The vacuum cleaner's motor generates a flow of air that is directed through the machine's nozzle, creating a low-pressure area that sucks up dirt and dust. The air is then filtered before being released back into the room. At Resolved Analytics we are big fans of innovators and there is no greater innovator in consumer products over the last 100 years than the “king of suck” James Dyson. We are such big fans that we did an entire article his cyclone based innovation in vacuums.

Designers of vacuum cleaners use their knowledge of fluid dynamics to optimize the airflow and suction power of the machine. By understanding the behavior of airflows, they can create machines that are more efficient and quieter, making the cleaning process more comfortable and less time-consuming.

Stand Mixers

Stand mixers are another example of how fluid dynamics plays a crucial role in consumer products. The mixer's motor drives a set of beaters or a whisk that is immersed in a bowl of ingredients. The beaters create a flow pattern in the mixture that helps to blend the ingredients together evenly.

Designers of stand mixers use fluid dynamics to optimize the flow pattern created by the beaters. By understanding how the ingredients move in the bowl, they can create machines that are more efficient and produce better results.

Other Consumer Products

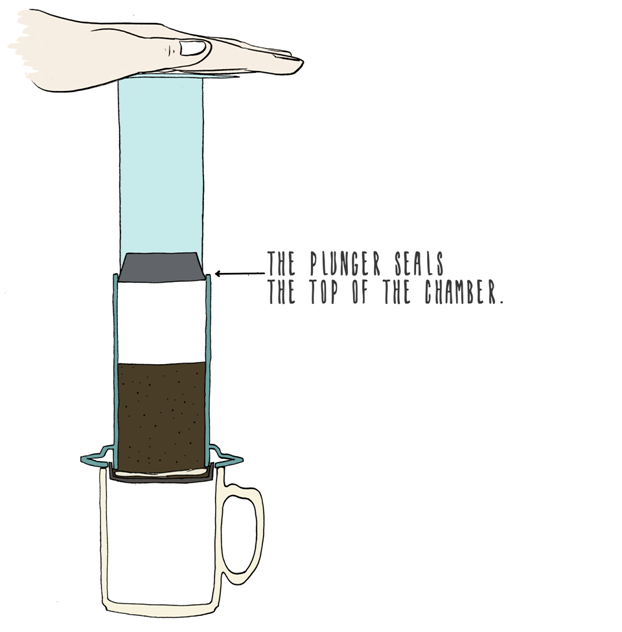

Fluid dynamics is also used in the design of many other consumer products, such as hair dryers, air conditioners, and even coffee makers. In hair dryers, for example, designers use fluid dynamics to optimize the airflow and temperature of the machine, ensuring that it dries hair quickly and efficiently without damaging it.

In air conditioners, fluid dynamics is used to create a flow of cool air that circulates around a room, keeping it at a comfortable temperature. By understanding how air flows through a space, designers can create air conditioners that are more energy-efficient and effective. Even coffee makers benefit from an understanding of fluid dynamics. By optimizing the flow and temperature of hot water through the machine, designers can create coffee makers that produce a better-tasting cup of coffee.

(The operation of the aeropress coffee maker – courtesy Colin McDonald / CNET)

Conclusion

Fluid dynamics is a fascinating field that has a significant impact on almost everything in our lives. By understanding how fluids behave, designers can create machines that are more efficient, powerful, and produce better results. As our understanding of fluid dynamics continues to evolve, we can expect to see even more incredible technological progress in the years to come.