Virtual Body Method in CFD: A Game-Changer for Fluid-Solid Interaction Simulations

Revolutionizing Moving Body Simulations in CFD

In computational fluid dynamics (CFD), accurately modeling interactions between moving solid bodies and surrounding fluids has long been a challenge. Traditional methods require complex mesh deformation or remeshing, leading to increased computational time and effort.

With the release of Simcenter STAR-CCM+ 2502, engineers now have access to the Virtual Body Method (VBM)—an innovative approach that simplifies these simulations, enhances efficiency, and delivers greater accuracy in real-world applications.

In the food processing industry, handling complex fluids like ice cream is anything but straightforward. These materials don’t flow like water—they have quirks, textures, and temperature-dependent properties that make prediction a challenge. But with advanced CFD simulation, engineers can cut through the guesswork. By modeling exactly how these fluids behave under real-world conditions, they can fine-tune manufacturing and filling processes, ensuring every swirl, pour, and scoop is optimized for efficiency and quality.

What Is the Virtual Body Method in CFD?

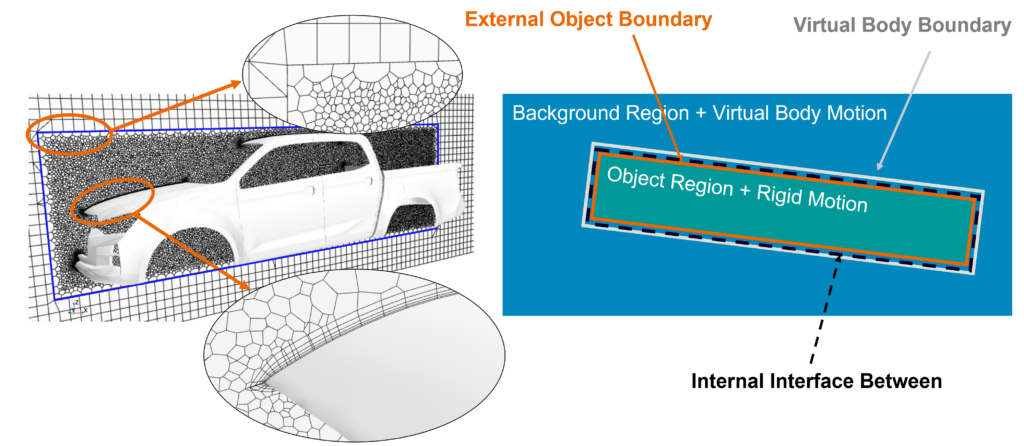

VBM is a specialized Immersed Boundary Method (IBM) designed to handle fluid-solid interactions efficiently. Unlike traditional methods, it does not require mesh modifications when dealing with moving bodies, making it ideal for industries like automotive, aerospace, and manufacturing.

How VBM Works

Uses a non-conforming mesh to represent moving solids.

Eliminates the need for continuous remeshing.

Efficiently captures fluid-solid interactions while reducing computational overhead.

Key Differences from Traditional CFD Approaches

No Mesh Deformation: Unlike body-fitted mesh techniques, VBM does not require updates to the computational grid.

Faster Simulations: By simplifying geometry representation, engineers can accelerate CFD workflows without sacrificing accuracy.

Improved Handling of Complex Motions: Ideal for applications with multiple moving parts, such as filling processes or rotating machinery.

The Virtual Body Method (VBM) takes a clever approach to handling moving objects in CFD. Instead of constantly reshaping the mesh, it simply deactivates the cells inside the object—much like the overset grid method. Then, the vertices near the object's new boundary are snapped into place, seamlessly conforming to the geometry.

This technique is all about flexibility. Engineers can define the virtual body’s surface to control how precisely the mesh adapts. Need high-fidelity results? Adaptive mesh refinement sharpens the resolution where it matters most. Looking for a quick, low-fidelity simulation for early design decisions? VBM keeps things efficient, offering a streamlined way to explore conceptual designs and preliminary performance assessments without the computational overhead.

Benefits of Using the Virtual Body Method

Implementing VBM in CFD simulations provides numerous advantages, including improved efficiency, reduced costs, and greater simulation accuracy.

Eliminates Complex Meshing Challenges

Traditional mesh-based approaches often struggle with dynamic movements in fluid-structure interactions. VBM removes this complexity, making it easier to simulate processes like liquid sloshing, mixing, and coating.

Accelerates Simulation Turnaround Time

By removing the need for manual mesh adjustments, VBM enables faster iterations, allowing engineers to optimize designs more efficiently.

Delivers Greater Accuracy for Moving Fluids

Ensures high-fidelity flow predictions even with intricate motion.

Captures transient effects critical in manufacturing and automotive applications.

Provides reliable data for process optimization.

Real-World Applications of VBM in Engineering

VBM is already transforming CFD simulations across multiple industries, improving precision and efficiency in various engineering applications.

Automotive Electro-Dip Coating

Simulates how paint flows over a vehicle body during electro-dipping.

Ensures uniform coating thickness while reducing material waste.

Liquid Filling in Manufacturing

Accurately models fluid dynamics inside containers during high-speed filling.

Prevents spillage, optimizes fill rates, and enhances production efficiency.

Pumping and Mixing Processes

Enhances simulation accuracy for fluid transport in piping systems.

Helps optimize pump efficiency, reducing energy consumption and operational costs.

How VBM Enhances CFD for Complex Simulations

With the ability to model fluid-solid interactions more effectively, VBM is an essential tool for engineers aiming to streamline CFD workflows while improving predictive capabilities.

Seamless Integration in CFD Workflows

Works within Simcenter STAR-CCM+, a leading CFD software solution.

Reduces pre-processing time, making simulations easier to set up and execute.

Future of VBM in Engineering Simulations

As industries demand faster, more accurate simulations, VBM is expected to play a key role in:

Advancing automotive and aerospace simulations for fuel efficiency.

Optimizing industrial fluid dynamics in mixing, transport, and packaging.

Enhancing virtual prototyping capabilities for engineering applications.

The Virtual Body Method (VBM) in Simcenter STAR-CCM+ 2502 is revolutionizing CFD simulations by eliminating meshing complexities, accelerating turnaround times, and improving fluid-solid interaction modeling. As engineering challenges grow, VBM empowers CFD specialists to innovate faster, optimize designs, and enhance real-world applications efficiently.