Fluid Dynamics Simulations and Design Services

Helping our customers address their critical fluid dynamics challenges since 2004.

Fluid dynamics can be tough, but with our CFD consulting team on your side you’ll have a great chance of success.

From the most complex multiphysics simulations and machine learning projects to basic design guidance, our team of fluid dynamics specialists are ready to help where needed.

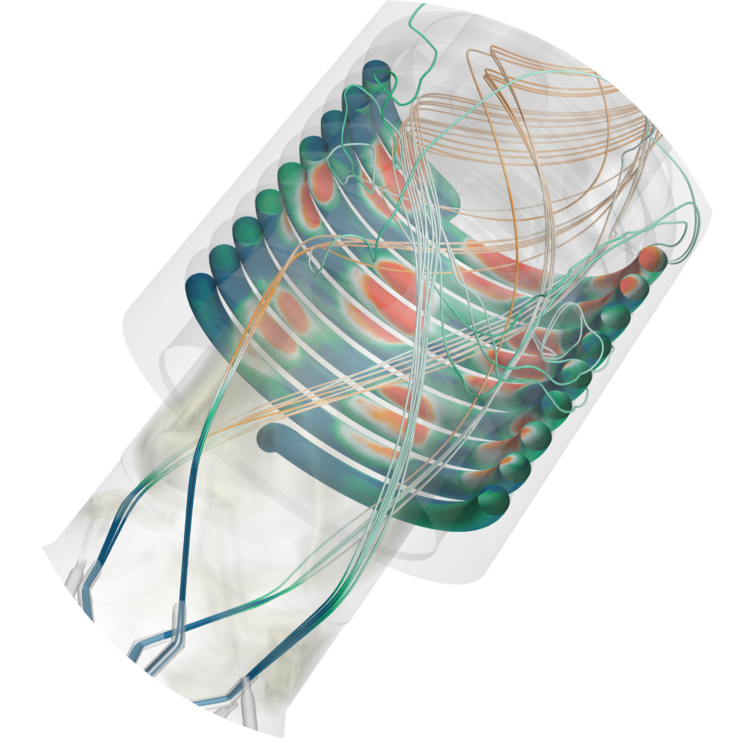

Our model is pretty simple: work to understand how your business priorities are tied to fluid dynamics and then take the lead in applying computational fluid dynamics tools and knowhow to meeting those objectives. Most projects are completed successfully within two to four weeks of conceptualization. Both this model, and our skills in executing it, have evolved and progressed over several hundred customer projects delivered since 2004.

HOW WE FLOW TOGETHER

Our 7 Step CFD Service Project

—

1. Schedule a discovery call and together we can decide what is needed to achieve your business objectives.

LET'S GET STARTED2. Receive a quote within 24 hours. Our standard two-week service package meets most clients' needs.

LET'S GET STARTED3. Within a day of release, a kickoff call gets the project off on the right foot. Information needs are identified.

LET'S GET STARTED4. We issue a project context document outlining project background, deliverables, schedule and expected outcomes making clear the value to be delivered.

LET'S GET STARTED5. We work collaboratively and quickly to meet objectives, maintaining a focus on how business metrics will be impacted by fluid dynamics.

LET'S GET STARTED6. The project document is updated with simulation results as they come in and interim meeting are used to discuss and define next steps

LET'S GET STARTED7. Achieve greatness.

LET'S GET STARTED

Client Testimonials